- Home

- >

- Products

- >

- tubular trolley wire

- >

tubular trolley wire

SJF multipole conductor system is a safe,economic,widely used reliable power supply devices for mobile electrification applications,is good replacement for cables and traditional steel conductors.It is classified as plastic and aluminum alloy ones as per housing material.Poles from 3 to 16,no oxygen copper as conductor material

- Information

| ltem | Data |

| Voltage Resistant | >25KV/min |

| IP | IP23 |

| Current Resistant | 10 times rated current,1s |

| Max Current | 1.5 times rated current, 30min |

| Insulation Dielectric Strength | Industrial frequency ac 3000v,1min no breakdown and flashover |

| Insulation Resistance | R>10MΩ |

| Pollution Grade | IV(general inductive du st,condensation) |

| Working Voltage | DC:1000V or AC:66V |

| Fire Retardant | Bunsens burner,qualified,good fire-retardant |

| Speed Of Collector | V:120m/min |

| Model | Code | Cross-section mm² | Rated Current A | Resistance Q/km | Impedance Ω/km |  |

| SJFS-3-70/210 | 0810301 | 70 | 210 | 0.257 | 0.292 | |

| SJFS-3-95/270 | 0810302 | 95 | 270 | 0.189 | 0.213 | |

| SJFS-3-120/320 | 0810303 | 120 | 320 | 0.150 | 0.191 | |

| SJFS-3-150/360 | 0810304 | 150 | 360 | 0.120 | 0.165 | |

| SJFS-4-10/50 | 0810401A | 10 | 50 | 1.800 | 1.896 |  |

| SJFS-4-16/80 | 0810402A | 16 | 80 | 1.125 | 1.189 | |

| SJFS-4-25/125 | 0810403A | 25 | 125 | 0.720 | 0.770 | |

| SJFS-4-35/140 | 0810404A | 35 | 140 | 0.514 | 0.558 | |

| SJFS-4-50/170 | 0810405A | 50 | 170 | 0.360 | 0.403 | |

| SJFS-4-70/210 | 0810406A | 70 | 210 | 0.257 | 0.302 | |

| SJF2S-4-10/50 | 0810401B | 10 | 50 | 1.800 | 1.896 |  |

| SJF2S-4-16/80 | 0810402B | 16 | 80 | 1.125 | 1.189 | |

| SJF2S-4-25/125 | 0810403B | 25 | 125 | 0.720 | 0.770 | |

| SJF2S-4-35/140 | 0810404B | 35 | 140 | 0.514 | 0.558 | |

| SJF2S-4-50/170 | 0810405B | 50 | 170 | 0.360 | 0.403 | |

| SJF2S-4-70/210 | 0810406B | 70 | 210 | 0.257 | 0.302 | |

| SJF3S-4-10/50 | 0810401C | 10 | 50 | 1.800 | 1.896 |  |

| SJF3S-4-16/80 | 0810402C | 16 | 80 | 1.125 | 1.189 | |

| SJF3S-4-25/125 | 0810403C | 25 | 125 | 0.720 | 0.770 | |

| SJF2S-5-10/50 | 0810501A | 10 | 50 | 1.800 | 1.896 |  |

| SJF2S-5-16/80 | 0810502A | 16 | 80 | 1.125 | 1.190 | |

| SJF2S-5-25/125 | 0810503A | 25 | 125 | 0.720 | 0.769 | |

| SJF4S-5-10/50F | 0810501B | 10 | 50 | 1.800 | 1.896 |  |

| SJF4S-5-16/80F | 0810502B | 16 | 80 | 1.125 | 1.190 | |

| SJF4S-5-25/125F | 0810503A | 25 | 125 | 0.720 | 0.770 | |

| SJF4S-5-35/140F | 0810504B | 35 | 140 | 0.514 | 0.559 | |

| SJF4S-5-50/170F | 0810505B | 50 | 170 | 0.360 | 0.403 | |

| SJF4S-5-70/210F | 0810506B | 70 | 210 | 0.257 | 0.303 | |

| SJFS-6-10/50 | 0810601A | 10 | 50 | 1.543 | 1.626 |  |

| SJFS-6-16/80 | 0810602A | 16 | 80 | 0.964 | 1.021 | |

| SJFS-7-10/50 | 0810701A | 10 | 50 | 1.800 | 1.897 |  |

| SJFS-7-16/80 | 0810702A | 16 | 80 | 1.125 | 1.191 | |

| SJF2S-6-10/50 | 0810601B | 10 | 50 | 1.542 | 1.626 |  |

| SJF2S-6-16/80 | 0810602B | 16 | 80 | 0.964 | 1.021 | |

| SJF2S-6-25/125 | 0810603B | 25 | 125 | 0.617 | 0.660 | |

| SJF2S-6-35/140 | 0810604B | 35 | 140 | 0.440 | 0.479 | |

| SJF2S-7-10/50 | 0810701B | 10 | 50 | 1.800 | 1.896 |  |

| SJF2S-7-16/80 | 0810702B | 16 | 80 | 1.125 | 1.190 | |

| SJF2S-7-25/125 | 0810703B | 25 | 125 | 0.720 | 0.770 | |

| SJF2S-7-35/140 | 0810704B | 35 | 140 | 0.514 | 0.559 | |

| SJFS-10-10/50 | 0811001 | 10 | 50 | 1.800 | 1.897 |  |

| SJFS-10-16/80 | 0811002 | 16 | 80 | 1.125 | 1.192 | |

| SJFS-10-25/125 | 0811003 | 25 | 125 | 0.720 | 0.771 | |

| SJFS-16-10/50F | 0811601 | 10 | 50 | 1.800 | 1.896 |  |

| SJFS-16-16/80F | 0811602 | 16 | 80 | 1.125 | 1.191 |

| Model | Code | Cross-section mm² | Rated Current A | Resistance Q/km | Impedance Ω/km |  |

| SJFL2-4-10/50 | 0820401A | 10 | 50 | 1.800 | 1.896 | |

| SJFL2-4-16/80 | 0820402A | 16 | 80 | 1.125 | 1.189 | |

| SJFL2-4-25/125 | 0820403A | 25 | 125 | 0.720 | 0.770 | |

| SJFL2-4-35/140 | 0820404A | 35 | 140 | 0.514 | 0.558 | |

| SJFL2-4-50/170 | 0820405A | 50 | 170 | 0.360 | 0.403 | |

| SJFL2-4-70/210 | 0820406A | 70 | 210 | 0.257 | 0.302 | |

| SJFL2-4-95/270 | 0820407A | 95 | 270 | 0.189 | 0.254 | |

| SJFL2-4-120/320 | 0820408A | 120 | 320 | 0.150 | 0.219 | |

| SJFL2-4-150/360 | 0820409A | 150 | 360 | 0.120 | 0.195 | |

| SJFL-5-10/50 | 0820401B | 10 | 50 | 1.800 | 1.897 |  |

| SJFL-5-16/80 | 0820402B | 16 | 80 | 1.125 | 1.205 | |

| SJFL-5-25/125 | 0820403B | 25 | 125 | 0.720 | 0.780 | |

| SJFL-5-35/140 | 0820404B | 35 | 140 | 0.514 | 0.568 | |

| SJFL-5-50/170 | 0820405B | 50 | 170 | 0.360 | 0.410 | |

| SJFL-5-70/210 | 0820406B | 70 | 210 | 0.257 | 0.302 | |

| SJFJ-5-95/270 | 0820407B | 95 | 270 | 0.189 | 0.240 | |

| SJFL-5-10/50 | 0820501 | 10 | 50 | 1.800 | 1.897 |  |

| SJFL-5-16/80 | 0820502 | 16 | 80 | 1.125 | 1.205 | |

| SJFL-5-25/125 | 0820503 | 25 | 125 | 0.720 | 0.780 | |

| SJFL-5-35/140 | 0820504 | 35 | 140 | 0.514 | 0.568 | |

| SJFL-5-50/170 | 0820505 | 50 | 170 | 0.360 | 0.410 | |

| SJFL-5-70/210 | 0820506 | 70 | 210 | 0.257 | 0.302 | |

| SJFJ-5-95/270 | 0820507 | 95 | 270 | 0.189 | 0.240 | |

| SJFL-7-10/50F | 0820701 | 10 | 50 | 1.800 | 1.896 |  |

| SJFL-7-16/80F | 0820702 | 16 | 80 | 1.125 | 1.190 | |

| SJFL-7-25/125F | 0820703 | 25 | 125 | 0.720 | 0.770 | |

| SJEL-7-35/130F | 0820704 | 35 | 140 | 0.514 | 0.559 | |

| SJFL-10-10/50F | 0821001 | 10 | 50 | 1.800 | 1.898 |  |

| SJFL-10-16/80F | 0821002 | 16 | 80 | 1.125 | 1.193 | |

| SJFJ-10-25/125F | 0821003 | 25 | 125 | 0.720 | 0.771 | |

| SJFL-16-10/50 | 0821601 | 10 | 50 | 1.800 | 1.898 |  |

| SJFL-16-16/80 | 0821602 | 16 | 80 | 1.125 | 1.194 |

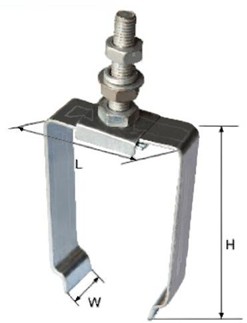

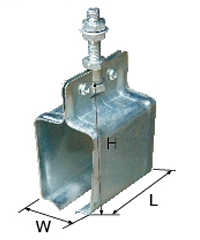

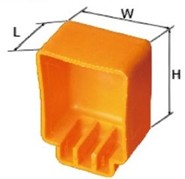

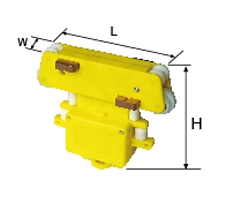

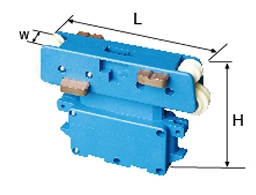

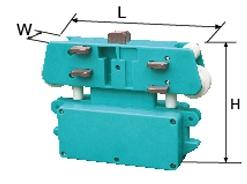

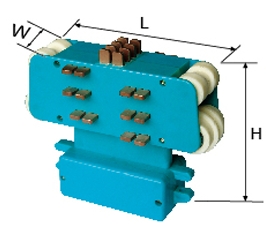

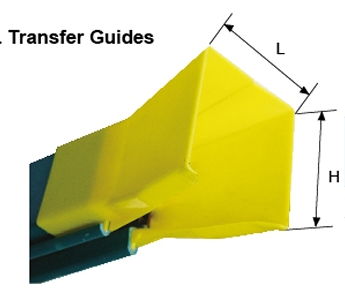

| Model | Code | Dimension | Weight KG | |||

| L | H | W | M | |||

| GXD-57 | 0810532 | 57 | 70 | 25 | 10 | 0.20 |

| GXD-64 | 0810330 | 64 | 100 | 25 | 10 | 0.24 |

| GXD-70 | 0810533 | 70 | 120 | 20 | 10 | 0.28 |

| GXD-78 | 0810534 | 78 | 128 | 25 | 10 | 0.29 |

| GXD-110 | 0810535 | 110 | 170 | 30 | 12 | 0.35 |

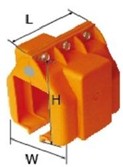

| Model | Code | Dimension | ||

| L | H | W | ||

| GGD-1 | 0810540 | 57 | 70 | 60 |

| GGD-2 | 0810541 | 78 | 110 | 60 |

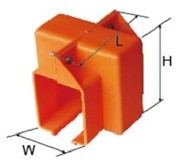

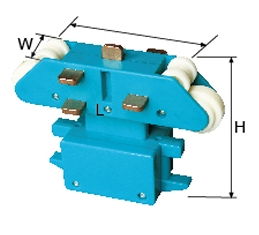

| Model | Code | Dimension | ||

| L | H | W | ||

| GLJ-1 | 0810545 | 57 | 70 | 63 |

| GLJ-2 | 0810546 | 108 | 104 | 63 |

| GLJ-3 | 0810645 | 123 | 126 | 105 |

| GLJ-4 | 0810646 | 106 | 114 | 110 |

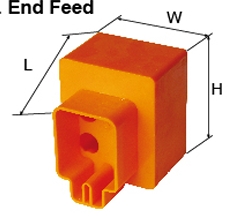

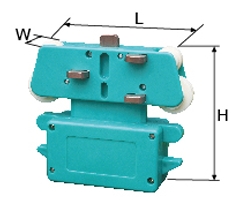

| Model | Code | Dimension | ||

| L | H | W | ||

| GZG-1 | 0810550 | 57 | 70 | 98 |

| GZG-2 | 0810551 | 105 | 116 | 98 |

| Model | Code | Dimension | ||

| L | H | W | ||

| GDG-1 | 0810555 | 57 | 70 | 100 |

| GDG-2 | 0810556 | 110 | 118 | 100 |

| Model | Code | Dimension | ||

| L | H | W | ||

| GDM-1 | 0810556 | 57 | 70 | 62 |

| GDM-2 | 0810656 | 41 | 87 | 62 |

| GDM-3 | 0811656 | 40 | 80 | 70 |

| GDM-4 | 0811657 | 59 | 125 | 105 |

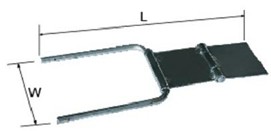

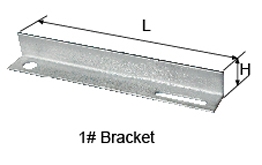

| Model | Code | Dimension | |

| L | H | ||

| GBC-1 | 0810010 | 330 | 90 |

| GBC-2 | 0810020 | 330 | 140 |

| GBC-3 | 0810021 | 330 | 240 |

| GBC-4 | 0810022 | 330 | 190 |

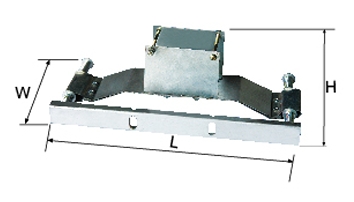

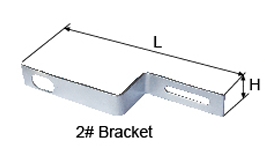

| Model | Code | Dimension | ||

| L | H | W | ||

| GTB-1 | 0810030 | 330 | 110 | 150 |

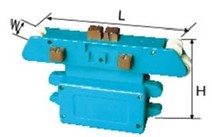

| Model | Code | Dimension | Weight KG | ||

| L | H | W | |||

| SJS-3-100 | 0810361 | 250 | 170 | 40 | 1.10 |

| Model | Code | Dimension | Weight KG | ||

| L | H | W | |||

| SJS-4-60 | 0810462A | 150 | 160 | 36 | 0.72 |

| SJS-4-150 | 0810463A | 250 | 200 | 35 | 1.56 |

| Model | Code | Dimension | Weight KG | ||

| L | H | W | |||

| SJS-4-60 | 0810462B | 160 | 150 | 35 | 0.6 |

| SJS-4-20 | 0810463B | 115 | 120 | 32 | 0.30 |

| Model | Code | Dimension | Weight KG | ||

| L | H | W | |||

| SJS-7-25 | 0810767 | 130 | 140 | 42 | 0.70 |

| Model | Code | Dimension | Weight KG | ||

| L | H | W | |||

| SJS-7-25 | 0810768 | 130 | 140 | 42 | 0.70 |

| Model | Code | Dimension | Weight KG | ||

| L | H | W | |||

| SJS-10-30 | 0811069 | 220 | 190 | 42 | 1.40 |

| Model | Code | Dimension | Weight KG | ||

| L | H | W | |||

| SJS-16-25 | 0811670 | 220 | 210 | 72 | 2.20 |

| Model | Code | Dimension | Weight KG | |

| L | H | |||

| GZJ-1 | 0811671 | 300 | 40 | 0.60 |

| Model | Code | Dimension | Weight KG | |

| L | H | |||

| GZJ-Ⅱ | 0811672 | 300 | 38 | 0.30 |

| Model | Code | Dimension | Weight KG | |

| L | H | |||

| GLB-1 | 0810081 | 10 | 10 | 0.30 |

As a power supply device for mobile equipment, the tubular sliding contact line has the following significant advantages:

1. The power supply performance of the tubular sliding contact line is stable and reliable

• Excellent electrical conductivity: Tubular sliding contact lines are typically made of copper or aluminum alloy materials with high electrical conductivity, featuring low resistance and low energy loss during current transmission. They can efficiently provide power to mobile devices, ensuring stable operation of the equipment. For instance, in some large factories, equipment such as cranes is powered by tubular sliding contact lines and can operate continuously for long periods of time. Power supply interruptions are extremely rare.

• Low voltage drop: Its structural design ensures that the voltage drop during current transmission remains within a reasonable range. Even in longer power supply lines, it can guarantee that mobile devices receive a stable voltage, meeting the voltage requirements for normal operation of the equipment and avoiding excessive voltage fluctuations that may affect equipment performance or cause damage.

Second, the tubular sliding contact line has high safety performance

• Good protective performance: Tubular sliding contact lines are generally protected by a casing, which is usually made of high-strength and well-insulating materials, effectively preventing electric shock to personnel and ensuring the safety of operators. In some places with extremely high safety requirements, such as chemical workshops, this protective performance is particularly important, which can prevent safety accidents caused by accidental contact with sliding contact lines.

• Dust-proof and water-proof design: Some tubular sliding contact lines have dust-proof and water-proof functions, which can adapt to relatively harsh environmental conditions. For instance, in outdoor environments or workshops with heavy dust, the dust-proof and water-proof design can prevent dust and moisture from entering the interior of the sliding contact line, avoiding safety accidents caused by short circuits and other faults, and extending the service life of the sliding contact line.

Third, the installation and maintenance of the tubular sliding contact line are convenient

• Flexible installation: The tubular sliding contact line has various installation methods. It can be installed horizontally, vertically or at an Angle according to the actual situation on site, adapting to different spatial layouts and equipment operation trajectories. During the installation process, no complex civil engineering works are required. The installation period is short and it can be put into use quickly, reducing the impact on production.

• Simple maintenance: Its structure is relatively simple, allowing maintenance personnel to conveniently inspect, clean and repair the sliding contact line. For instance, when dirt or foreign objects are found on the surface of the sliding contact line, maintenance personnel can easily open the casing for cleaning. If problems such as collector wear occur, components can also be replaced quickly, reducing maintenance costs and difficulty.

Fourth, the tubular sliding contact line has a long service life

• Good wear resistance: The conductors and collectors of the tubular sliding contact line are usually made of wear-resistant materials. During long-term use, they can withstand frequent friction between the collectors and the conductors, reduce wear and extend service life. For instance, in some logistics equipment that requires frequent starts and stops, the tubular sliding contact line can still maintain good electrical conductivity and mechanical properties after long-term operation.

• Strong corrosion resistance: For some tubular sliding contact lines used in damp or corrosive gas environments, special anti-corrosion treatment processes such as galvanization and powder coating are adopted to enhance their corrosion resistance, enabling them to operate stably for a long time in harsh conditions and reducing the frequency of faults and replacements caused by corrosion.

Five. The tubular sliding contact line is neat and tidy

• Neat appearance: The tubular sliding contact line has a neat appearance and smooth lines. After installation, it can make the entire power supply system look more beautiful and standardized. In some places that have requirements for environmental aesthetics, such as modern industrial plants and shopping malls, tubular sliding contact lines will not spoil the overall beauty of the environment; instead, they can enhance the overall image of the place.