- Home

- >

- Products

- >

- Tubular sliding line

- >

Tubular sliding line

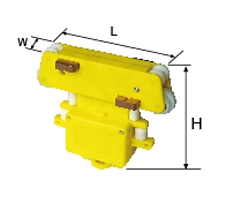

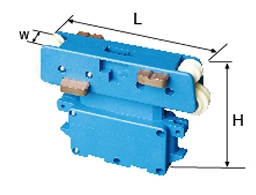

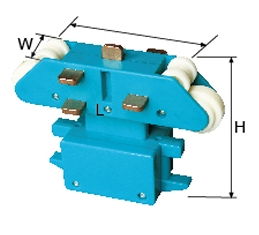

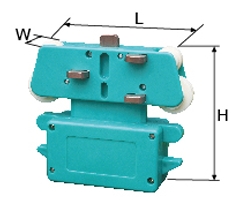

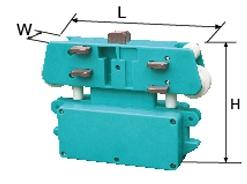

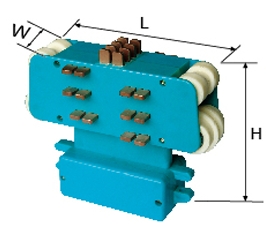

SJF multipole conductor system is a safe,economic,widely used reliable power supply devices for mobile electrification applications,is good replacement for cables and traditional steel conductors.It is classified as plastic and aluminum alloy ones as per housing material.Poles from 3 to 16,no oxygen copper as conductor material

- Information

| ltem | Data |

| Voltage Resistant | >25KV/min |

| IP | IP23 |

| Current Resistant | 10 times rated current,1s |

| Max Current | 1.5 times rated current, 30min |

| Insulation Dielectric Strength | Industrial frequency ac 3000v,1min no breakdown and flashover |

| Insulation Resistance | R>10MΩ |

| Pollution Grade | IV(general inductive du st,condensation) |

| Working Voltage | DC:1000V or AC:66V |

| Fire Retardant | Bunsens burner,qualified,good fire-retardant |

| Speed Of Collector | V:120m/min |

| Model | Code | Cross-section mm² | Rated Current A | Resistance Q/km | Impedance Ω/km |  |

| SJFS-3-70/210 | 0810301 | 70 | 210 | 0.257 | 0.292 | |

| SJFS-3-95/270 | 0810302 | 95 | 270 | 0.189 | 0.213 | |

| SJFS-3-120/320 | 0810303 | 120 | 320 | 0.150 | 0.191 | |

| SJFS-3-150/360 | 0810304 | 150 | 360 | 0.120 | 0.165 | |

| SJFS-4-10/50 | 0810401A | 10 | 50 | 1.800 | 1.896 |  |

| SJFS-4-16/80 | 0810402A | 16 | 80 | 1.125 | 1.189 | |

| SJFS-4-25/125 | 0810403A | 25 | 125 | 0.720 | 0.770 | |

| SJFS-4-35/140 | 0810404A | 35 | 140 | 0.514 | 0.558 | |

| SJFS-4-50/170 | 0810405A | 50 | 170 | 0.360 | 0.403 | |

| SJFS-4-70/210 | 0810406A | 70 | 210 | 0.257 | 0.302 | |

| SJF2S-4-10/50 | 0810401B | 10 | 50 | 1.800 | 1.896 |  |

| SJF2S-4-16/80 | 0810402B | 16 | 80 | 1.125 | 1.189 | |

| SJF2S-4-25/125 | 0810403B | 25 | 125 | 0.720 | 0.770 | |

| SJF2S-4-35/140 | 0810404B | 35 | 140 | 0.514 | 0.558 | |

| SJF2S-4-50/170 | 0810405B | 50 | 170 | 0.360 | 0.403 | |

| SJF2S-4-70/210 | 0810406B | 70 | 210 | 0.257 | 0.302 | |

| SJF3S-4-10/50 | 0810401C | 10 | 50 | 1.800 | 1.896 |  |

| SJF3S-4-16/80 | 0810402C | 16 | 80 | 1.125 | 1.189 | |

| SJF3S-4-25/125 | 0810403C | 25 | 125 | 0.720 | 0.770 | |

| SJF2S-5-10/50 | 0810501A | 10 | 50 | 1.800 | 1.896 |  |

| SJF2S-5-16/80 | 0810502A | 16 | 80 | 1.125 | 1.190 | |

| SJF2S-5-25/125 | 0810503A | 25 | 125 | 0.720 | 0.769 | |

| SJF4S-5-10/50F | 0810501B | 10 | 50 | 1.800 | 1.896 |  |

| SJF4S-5-16/80F | 0810502B | 16 | 80 | 1.125 | 1.190 | |

| SJF4S-5-25/125F | 0810503A | 25 | 125 | 0.720 | 0.770 | |

| SJF4S-5-35/140F | 0810504B | 35 | 140 | 0.514 | 0.559 | |

| SJF4S-5-50/170F | 0810505B | 50 | 170 | 0.360 | 0.403 | |

| SJF4S-5-70/210F | 0810506B | 70 | 210 | 0.257 | 0.303 | |

| SJFS-6-10/50 | 0810601A | 10 | 50 | 1.543 | 1.626 |  |

| SJFS-6-16/80 | 0810602A | 16 | 80 | 0.964 | 1.021 | |

| SJFS-7-10/50 | 0810701A | 10 | 50 | 1.800 | 1.897 |  |

| SJFS-7-16/80 | 0810702A | 16 | 80 | 1.125 | 1.191 | |

| SJF2S-6-10/50 | 0810601B | 10 | 50 | 1.542 | 1.626 |  |

| SJF2S-6-16/80 | 0810602B | 16 | 80 | 0.964 | 1.021 | |

| SJF2S-6-25/125 | 0810603B | 25 | 125 | 0.617 | 0.660 | |

| SJF2S-6-35/140 | 0810604B | 35 | 140 | 0.440 | 0.479 | |

| SJF2S-7-10/50 | 0810701B | 10 | 50 | 1.800 | 1.896 |  |

| SJF2S-7-16/80 | 0810702B | 16 | 80 | 1.125 | 1.190 | |

| SJF2S-7-25/125 | 0810703B | 25 | 125 | 0.720 | 0.770 | |

| SJF2S-7-35/140 | 0810704B | 35 | 140 | 0.514 | 0.559 | |

| SJFS-10-10/50 | 0811001 | 10 | 50 | 1.800 | 1.897 |  |

| SJFS-10-16/80 | 0811002 | 16 | 80 | 1.125 | 1.192 | |

| SJFS-10-25/125 | 0811003 | 25 | 125 | 0.720 | 0.771 | |

| SJFS-16-10/50F | 0811601 | 10 | 50 | 1.800 | 1.896 |  |

| SJFS-16-16/80F | 0811602 | 16 | 80 | 1.125 | 1.191 |

| Model | Code | Cross-section mm² | Rated Current A | Resistance Q/km | Impedance Ω/km |  |

| SJFL2-4-10/50 | 0820401A | 10 | 50 | 1.800 | 1.896 | |

| SJFL2-4-16/80 | 0820402A | 16 | 80 | 1.125 | 1.189 | |

| SJFL2-4-25/125 | 0820403A | 25 | 125 | 0.720 | 0.770 | |

| SJFL2-4-35/140 | 0820404A | 35 | 140 | 0.514 | 0.558 | |

| SJFL2-4-50/170 | 0820405A | 50 | 170 | 0.360 | 0.403 | |

| SJFL2-4-70/210 | 0820406A | 70 | 210 | 0.257 | 0.302 | |

| SJFL2-4-95/270 | 0820407A | 95 | 270 | 0.189 | 0.254 | |

| SJFL2-4-120/320 | 0820408A | 120 | 320 | 0.150 | 0.219 | |

| SJFL2-4-150/360 | 0820409A | 150 | 360 | 0.120 | 0.195 | |

| SJFL-5-10/50 | 0820401B | 10 | 50 | 1.800 | 1.897 |  |

| SJFL-5-16/80 | 0820402B | 16 | 80 | 1.125 | 1.205 | |

| SJFL-5-25/125 | 0820403B | 25 | 125 | 0.720 | 0.780 | |

| SJFL-5-35/140 | 0820404B | 35 | 140 | 0.514 | 0.568 | |

| SJFL-5-50/170 | 0820405B | 50 | 170 | 0.360 | 0.410 | |

| SJFL-5-70/210 | 0820406B | 70 | 210 | 0.257 | 0.302 | |

| SJFJ-5-95/270 | 0820407B | 95 | 270 | 0.189 | 0.240 | |

| SJFL-5-10/50 | 0820501 | 10 | 50 | 1.800 | 1.897 |  |

| SJFL-5-16/80 | 0820502 | 16 | 80 | 1.125 | 1.205 | |

| SJFL-5-25/125 | 0820503 | 25 | 125 | 0.720 | 0.780 | |

| SJFL-5-35/140 | 0820504 | 35 | 140 | 0.514 | 0.568 | |

| SJFL-5-50/170 | 0820505 | 50 | 170 | 0.360 | 0.410 | |

| SJFL-5-70/210 | 0820506 | 70 | 210 | 0.257 | 0.302 | |

| SJFJ-5-95/270 | 0820507 | 95 | 270 | 0.189 | 0.240 | |

| SJFL-7-10/50F | 0820701 | 10 | 50 | 1.800 | 1.896 |  |

| SJFL-7-16/80F | 0820702 | 16 | 80 | 1.125 | 1.190 | |

| SJFL-7-25/125F | 0820703 | 25 | 125 | 0.720 | 0.770 | |

| SJEL-7-35/130F | 0820704 | 35 | 140 | 0.514 | 0.559 | |

| SJFL-10-10/50F | 0821001 | 10 | 50 | 1.800 | 1.898 |  |

| SJFL-10-16/80F | 0821002 | 16 | 80 | 1.125 | 1.193 | |

| SJFJ-10-25/125F | 0821003 | 25 | 125 | 0.720 | 0.771 | |

| SJFL-16-10/50 | 0821601 | 10 | 50 | 1.800 | 1.898 |  |

| SJFL-16-16/80 | 0821602 | 16 | 80 | 1.125 | 1.194 |

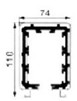

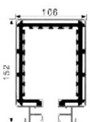

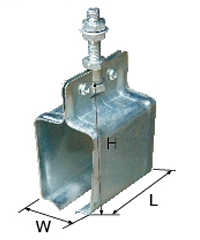

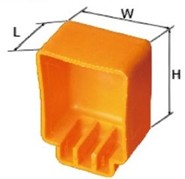

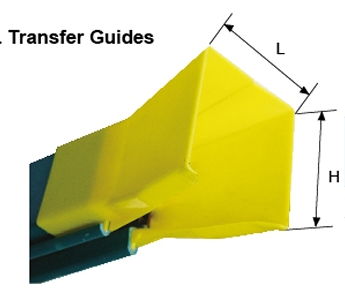

| Model | Code | Dimension | Weight KG | |||

| L | H | W | M | |||

| GXD-57 | 0810532 | 57 | 70 | 25 | 10 | 0.20 |

| GXD-64 | 0810330 | 64 | 100 | 25 | 10 | 0.24 |

| GXD-70 | 0810533 | 70 | 120 | 20 | 10 | 0.28 |

| GXD-78 | 0810534 | 78 | 128 | 25 | 10 | 0.29 |

| GXD-110 | 0810535 | 110 | 170 | 30 | 12 | 0.35 |

| Model | Code | Dimension | ||

| L | H | W | ||

| GGD-1 | 0810540 | 57 | 70 | 60 |

| GGD-2 | 0810541 | 78 | 110 | 60 |

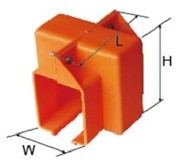

| Model | Code | Dimension | ||

| L | H | W | ||

| GLJ-1 | 0810545 | 57 | 70 | 63 |

| GLJ-2 | 0810546 | 108 | 104 | 63 |

| GLJ-3 | 0810645 | 123 | 126 | 105 |

| GLJ-4 | 0810646 | 106 | 114 | 110 |

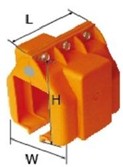

| Model | Code | Dimension | ||

| L | H | W | ||

| GZG-1 | 0810550 | 57 | 70 | 98 |

| GZG-2 | 0810551 | 105 | 116 | 98 |

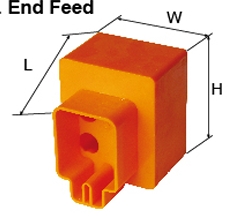

| Model | Code | Dimension | ||

| L | H | W | ||

| GDG-1 | 0810555 | 57 | 70 | 100 |

| GDG-2 | 0810556 | 110 | 118 | 100 |

| Model | Code | Dimension | ||

| L | H | W | ||

| GDM-1 | 0810556 | 57 | 70 | 62 |

| GDM-2 | 0810656 | 41 | 87 | 62 |

| GDM-3 | 0811656 | 40 | 80 | 70 |

| GDM-4 | 0811657 | 59 | 125 | 105 |

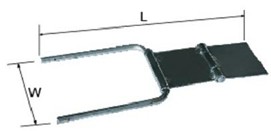

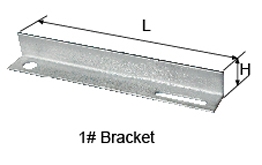

| Model | Code | Dimension | |

| L | H | ||

| GBC-1 | 0810010 | 330 | 90 |

| GBC-2 | 0810020 | 330 | 140 |

| GBC-3 | 0810021 | 330 | 240 |

| GBC-4 | 0810022 | 330 | 190 |

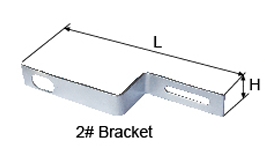

| Model | Code | Dimension | ||

| L | H | W | ||

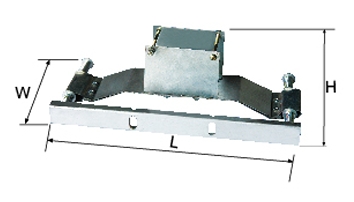

| GTB-1 | 0810030 | 330 | 110 | 150 |

| Model | Code | Dimension | Weight KG | ||

| L | H | W | |||

| SJS-3-100 | 0810361 | 250 | 170 | 40 | 1.10 |

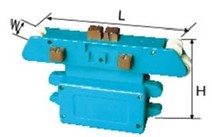

| Model | Code | Dimension | Weight KG | ||

| L | H | W | |||

| SJS-4-60 | 0810462A | 150 | 160 | 36 | 0.72 |

| SJS-4-150 | 0810463A | 250 | 200 | 35 | 1.56 |

| Model | Code | Dimension | Weight KG | ||

| L | H | W | |||

| SJS-4-60 | 0810462B | 160 | 150 | 35 | 0.6 |

| SJS-4-20 | 0810463B | 115 | 120 | 32 | 0.30 |

| Model | Code | Dimension | Weight KG | ||

| L | H | W | |||

| SJS-7-25 | 0810767 | 130 | 140 | 42 | 0.70 |

| Model | Code | Dimension | Weight KG | ||

| L | H | W | |||

| SJS-7-25 | 0810768 | 130 | 140 | 42 | 0.70 |

| Model | Code | Dimension | Weight KG | ||

| L | H | W | |||

| SJS-10-30 | 0811069 | 220 | 190 | 42 | 1.40 |

| Model | Code | Dimension | Weight KG | ||

| L | H | W | |||

| SJS-16-25 | 0811670 | 220 | 210 | 72 | 2.20 |

| Model | Code | Dimension | Weight KG | |

| L | H | |||

| GZJ-1 | 0811671 | 300 | 40 | 0.60 |

| Model | Code | Dimension | Weight KG | |

| L | H | |||

| GZJ-Ⅱ | 0811672 | 300 | 38 | 0.30 |

| Model | Code | Dimension | Weight KG | |

| L | H | |||

| GLB-1 | 0810081 | 10 | 10 | 0.30 |

Tubular sliding contact line (also known as closed sliding contact line or conduit sliding contact line) is a power supply system that encapsulates conductors in insulating protective tubes, mainly used in mobile power supply scenarios such as cranes and automated equipment. Compared with traditional bare wires or open sliding contact lines, it has the following significant advantages:

The tubular sliding contact line has high safety

Fully enclosed structure: The conductor is wrapped in an insulating tube to prevent the risk of electric shock and meet industrial safety standards (such as IP23 and IP54 protection levels).

Short-circuit and arc prevention: Prevent interphase short circuits or discharges caused by the entry of foreign objects (such as metal shavings and dust).

Flame-retardant materials: The shell is usually made of high-temperature resistant and fireproof engineering plastics or PVC to reduce the risk of fire.

2. The tubular sliding contact line is suitable for harsh environments

Waterproof and moisture-proof: The closed design effectively prevents erosion by rain and moisture, making it suitable for humid environments such as outdoors, ports, and metallurgy.

Corrosion-resistant and dust-proof: Suitable for environments with large amounts of dust and corrosive gases (such as chemical plants and electroplating workshops).

Resistance to high and low temperatures: Wide operating temperature range (-30℃ to 120℃), suitable for extreme climates.

3. The tubular sliding contact line provides stable power supply with low loss

Low-impedance conductor: Made of high-purity copper or aluminum alloy, it has good electrical conductivity and reduces power loss.

Voltage stability: The collector is in close contact with the guide rail, reducing current fluctuations and making it suitable for power supply to precision equipment.

No risk of power failure: Compared with segmented sliding contact lines, tubular sliding contact lines can adopt a seamless design to avoid power failure at the joints.

4. The tubular sliding contact line has a long service life and requires no maintenance

Wear-resistant and anti-aging: The collector is made of carbon brushes or copper-graphite materials, with low wear and a service life of over 10 years.

Almost maintenance-free: The closed structure reduces dust accumulation, eliminating the need for frequent cleaning or adjustment.

5. The tubular sliding contact line is flexible to install and saves space

Compact design: Small in size, suitable for space-constrained situations (such as low-rise factories).

Flexible installation: Some tubular sliding contact lines support arc-shaped or curved tracks, suitable for complex layouts.

Modular expansion: It can be easily lengthened or shortened to meet the requirements of different devices.

6. The tubular sliding contact line is economical and efficient

Low comprehensive cost: Although the initial investment is slightly higher, the long-term maintenance cost is low, the service life is long, and the cost performance is high.

Energy saving and power saving: Compared with cable drag chains or bare wire sliding contact lines, it has lower power loss.

The applicable scenarios of tubular sliding contact lines

· Lifting equipment: bridge cranes, gantry cranes, cantilever cranes, etc.

· Automated production lines: AGV carts, conveyors, and automated warehousing systems.

· Harsh environments: ports, metallurgy, chemical industry, food processing and other damp, dusty and corrosive environments.

Summary

Tubular sliding contact lines, with their advantages of high safety, resistance to harsh environments, long service life and maintenance-free operation, are particularly suitable for industrial Settings that are humid, dusty, corrosive or require high protection levels. Compared with traditional sliding contact lines, it can provide more stable and safer power transmission, reduce the failure rate, and is an ideal choice for power supply to heavy mobile equipment.