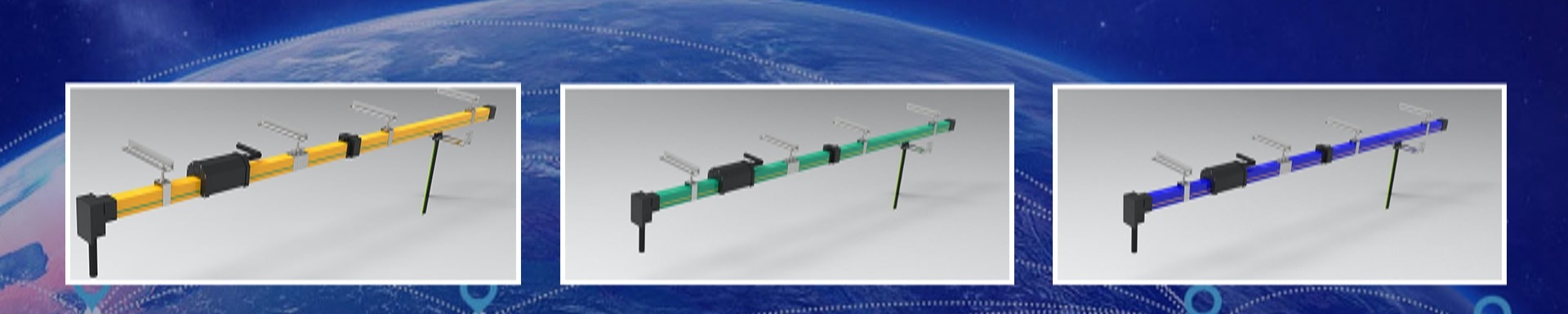

Multipolar tubular sliding contact line

The multi-pole tubular sliding contact line is composed of high-strength engineering plastic insulated conduits or aluminum alloy protective shells, multi-stage conductive copper bars, collectors, as well as suspension and fixation components. The multi-pole tubular sliding contact line is widely used in logistics automated assembly lines and inspection lines with low current and high usage frequency due to its compact design and safe operation.

- Information

The multi-pole tubular sliding contact line is composed of high-strength engineering plastic insulated conduits or aluminum alloy protective shells, multi-stage conductive copper bars, collectors, as well as suspension and fixation components. The multi-pole tubular sliding contact line is widely used in logistics automated assembly lines and inspection lines with low current and high usage frequency due to its compact design and safe operation.

Advantages of multi-pole tubular sliding contact lines:

As a mobile power supply system, the core advantages of the multi-pole tubular sliding contact line are mainly reflected in the following aspects:

1. Multipole TUBE sliding contact line SAFETY HIGH

Youdaoplaceholder0 Double protection design : The exterior is made of high-insulation PVC engineering plastic, with a protection grade of IP23, effectively protecting against rain, snow and foreign objects, and eliminating the risk of electric shock when personnel come into contact.

Youdaoplaceholder0 Arc resistance : The collector has excellent directional performance, reliable contact, can effectively suppress arc and serial arc phenomena, and reduce failure rate.

2. Multipole TUBE sliding contact line economy STRONG

Youdaoplaceholder0 Low energy consumption design : Copper conductors combined with low impedance structures (for example, the resistance of DHG-4-50 type is only 0.382Ω/km) reduce transmission loss by 15% compared with traditional steel sliding lines, achieving significant energy savings during long-term operation.

Youdaoplaceholder0 Low installation cost : Flexible combination of modular components (conduits, connectors), small bend radius, high installation efficiency, reducing the overall cost by about 20%.

3. Multipole TUBE sliding contact line structure compact flexible

Youdaoplaceholder0 Small space occupation : 3-16 power transmission copper bars (such as DHG-5-35 type) can be integrated into a single conduit, greatly saving installation space, especially suitable for narrow working conditions.

Youdaoplaceholder0 Modular expansion : Supports fixed-length (4 m/piece) splicing, can be quickly assembled with components such as aluminum joints and end covers, and has good adaptability to curves.

4. Multipole TUBE sliding contact line MAINTENANCE CONVENIENT

Youdaoplaceholder0 Component standardization : Collector, hanger, connector sheath and other accessories are highly versatile, easy to replace, only the wear of the brush needs to be checked daily.

Youdaoplaceholder0 Low failure rate Stable contact between conductor and collector, good anti-vibration performance, reduced frequency of shutdown for maintenance.

5. Multi-pole TUBE sliding contact LINE scene adaptability WIDE

Youdaoplaceholder0 Preferred light load equipment : Rated current covering 50A - 210A (e.g. DHG-4-70), perfectly matched with medium and small power equipment such as electric hoists and light cranes.

Youdaoplaceholder0 Multi-industry applications : Widely used in port transportation, automated production lines, logistics and warehousing, and workshop power supply systems, especially in sites that require frequent turns.