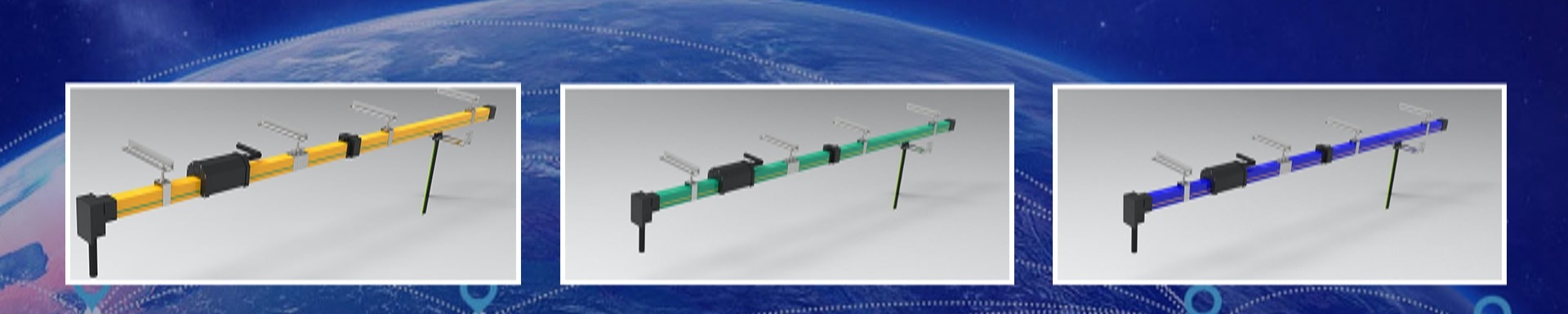

Single-pole aluminum sliding contact line

Product Overview of Single-pole Aluminum Sliding Contact Line:

Single-pole safety sliding wire is a new type of power supply system for feeding electricity to mobile mechanical equipment. The conductor is made of high-quality aluminum alloy profiles with a special formula, and its outer sheath is made of special polyvinyl chloride material, which plays a safety role in preventing rain, dust, snow and electric shock. With a simple structure and convenient installation and maintenance, it is widely used as power supply lines for mobile equipment in mines, metallurgy, chemical industry, machinery, docks, freight yards, etc.

- Information

Single-pole aluminum sliding contact line

(1) Product Overview of Single-pole Aluminum Sliding Contact Line:

Single-pole safety sliding wire is a new type of power supply system for feeding electricity to mobile mechanical equipment. The conductor is made of high-quality aluminum alloy profiles with a special formula, and its outer sheath is made of special polyvinyl chloride material, which plays a safety role in preventing rain, dust, snow and electric shock. With a simple structure and convenient installation and maintenance, it is widely used as power supply lines for mobile equipment in mines, metallurgy, chemical industry, machinery, docks, freight yards, etc.

(II) Product Features of single-pole aluminum sliding contact line:

1. Safe and reliable, there is no risk of electric shock even when touched by fingers, and it meets the IP23 standard.

2. Energy conservation and consumption reduction: Special formula aluminum alloy profiles are used as conductors. It has low resistance, which can reduce the loss of electrical energy and improve the efficiency of electrical energy utilization.

3. Long service life. The conductor sheath also adopts a unique formula, which greatly extends the service life of the sliding wire system.

4. The collector can move in three-dimensional space and can meet the uninterrupted power supply requirements of power supply equipment. It adopts a double insulation design, making the operation safer and more reliable.

5. New materials, new technologies and new processes ensure that the product has higher corrosion resistance, weather resistance and a wider range of working temperatures, and its working performance is safer and more reliable.

6. The light series is ≤500A, the heavy type I series is 630A to 1250A, and the heavy type II series is >1250A. For the same series, the sheaths and accessories are universal.

7. It adopts a combined design, which is easy to install and maintain on a daily basis.