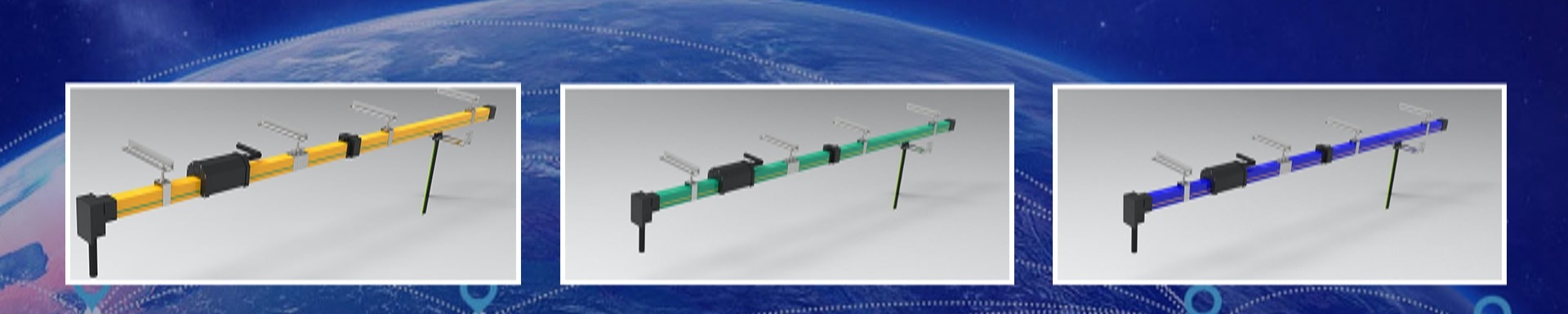

single-pole sliding contact line

Single-pole sliding contact line (also known as single-pole safety sliding contact line or single-pole power supply sliding contact line) is a system used for power supply to mobile equipment (such as cranes, electric hoists, automated production lines, etc.)。

Single-pole sliding contact lines stand out in terms of safety, durability, energy efficiency and ease of installation. They are an ideal choice for power supply to mobile devices, especially suitable for industrial environments that require stable power transmission.

- Information

| ltem | Data |

| Breakdown Voltage | 20KV/min |

| IP | IP23 |

| Withstand Current | 20 times rated current,1s |

| Insulation Dielectric Strength | 3000VAC industrial frequency,1min,no breakdown and flashover |

| Insulation Resistance | 10MΩ |

| Working Votlage | AC:660V or DC:1000V |

| Fire Retardance | Bunsens burner,qualified,good fire-retardant |

| Collector Working Speed | V≤360m/min |

| Model | Code | Cross-section mm² | Rated Current A | Resistance Ω/km | Impedance Ω/km | Support Bracket |

| SJDL-130/150 | 0831010 | 130 | 150 | 24×32 | 0.2154 | 0.2154 |

| SJDL-160/250 | 0831011 | 160 | 250 | 0.1905 | 0.2195 | |

| SJDL-198/320 | 0831012 | 198 | 320 | 33×42 | 0.1333 | 0.1333 |

| SJDL-320/500 | 0831013 | 320 | 500 | 0.0952 | 0.1455 | |

| SJDL-400/630 | 0831014 | 400 | 630 | 0.0762 | 0.1338 | |

| SJDL-500/800 | 0831015 | 500 | 800 | 0.0609 | 0.1258 | |

| SJDL-700/1000 | 0831016 | 700 | 1000 | 0.0435 | 0.1184 | |

| SJDL-800/1250 | 0831017 | 800 | 1250 | 0.0381 | 0.0987 | |

| SJDL-1200/1600 | 0831018 | 1200 | 1600 | 52×65 | 0.0254 | 0.0904 |

| SJDL-1600/2000 | 0831019 | 1600 | 2000 | 0.0190 | 0.0889 | |

| SJDL-2000/2500 | 0831020 | 2000 | 2500 | 0.0152 | 0.0881 |

| Model | Code | Cross-section mm² | Rated Current A | Resistance Ω/km | Impedance Ω/km | Support Bracket |

| SJDT-160/500 | 0832021 | 160 | 500 | 20×26 | 0.1161 | 0.1594 |

| SJDT-250/700 | 0832022 | 250 | 700 | 0.0743 | 0.1327 | |

| SJDT-320/1000 | 0832023 | 320 | 1000 | 32×42 | 0.0580 | 0.1244 |

| SJDT-400/1250 | 0832024 | 400 | 1250 | 0.0464 | 0.1194 | |

| SJDT-500/1600 | 0832025 | 500 | 1600 | 0.0372 | 0.1161 | |

| SJDT-700/2000 | 0832026 | 700 | 2000 | 0.0265 | 0.1132 |

| Model | Code | Cross-section mm² | Rated Current A | Resistance Ω/km | Impedance Ω/km | Support Bracket |

| SJDT-L-38.4/150 | 0833030 | 38.4 | 150 | 20×26 | 0.485 | 0.489 |

| SJDT-L-57.6/250 | 0833031 | 57.6 | 250 | 0.323 | 0.328 | |

| SJDT-L-75.6/320 | 0833032 | 75.6 | 320 | 32×42 | 0.246 | 0.250 |

| SJDT-L-140.4/500 | 0833033 | 140.4 | 500 | 0.124 | 0.128 |

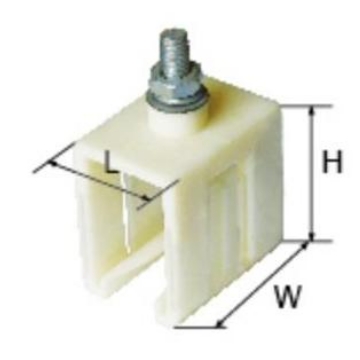

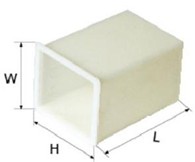

| Model | Code | Dimension | Weight KG | ||

| L | H | W | |||

| XDT-1 | 0835211 | 27 | 43 | 40 | 0.050 |

| XDT-2 | 0835212 | 31 | 46 | 55 | 0.075 |

| XDT-3 | 0835213 | 43 | 61 | 60 | 0.100 |

| XDT-4 | 0835214 | 63 | 88 | 76 | 0.150 |

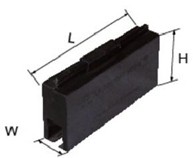

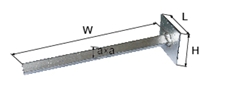

| Model | Code | Dimension | Weight KG | ||

| L | H | W | |||

| LJ-1 | 0835310 | 160 | 60 | 25 | 0.08 |

| LJ-2 | 0835311 | 240 | 90 | 45 | 0.20 |

| LJ-3 | 0835312 | 260 | 150 | 70 | 0.50 |

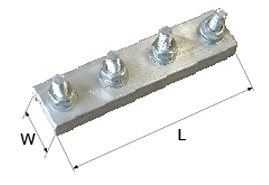

| Model | Code | Dimension | Weight KG | |

| L | W | |||

| DL-1 | 0835511 | 105 | 25 | 0.18 |

| DL-2 | 0835512 | 152 | 32 | 0.30 |

| DL-3 | 0835513 | 170 | 63 | 0.50 |

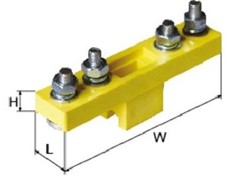

| Model | Code | Dimension | ||

| L | H | W | ||

| DM-1 | 0835331 | 78 | 35 | 42 |

| DM-2 | 0835332 | 70 | 53 | 43 |

| DM-3 | 0835333 | 80 | 80 | 65 |

| Model | Code | Dimension | |||

| L | axa | H | W | ||

| BC-1 | 0835611 | 100 | 25×25 | 100 | 330 |

| BC-2 | 0835612 | 100 | 25×25 | 100 | 410 |

| Model | Code | Dimension | ||

| L | H | W | ||

| JX-1 | 0835711 | 26.5 | 13 | 104.5 |

| JX-2 | 0835712 | 38 | 20 | 161 |

| JX-3 | 0835713 | 57 | 20 | 180 |

| Model | Code | Dimension | |

| L | H | ||

| SJDA-100 | S0835010 | 200 | 60 |

| Model | Code | Dimension | |

| L | H | ||

| SJDA-150 | 0835020 | 300 | 150 |

| Model | Code | Dimension | |

| L | H | ||

| SJDA-250 | 0835030 | 400 | 130 |

| Model | Code | Dimension | |

| L | H | ||

| SJDA-400 | 0835040 | 370 | 150 |

| Model | Code | Dimension | |

| L | H | ||

| SJDA-500 | 0835050 | 400 | 200 |

| Model | Code | Dimension | ||

| L | W | L1 | ||

| ZJI-3-80 | 0835811 | 370 | 40 | 80 |

| ZJI-3-120 | 0835812 | 380 | 50 | 120 |

| ZJI-4-80 | 0835813 | 450 | 40 | 80 |

| ZJI-4-120 | 0835814 | 500 | 50 | 120 |

| Model | Code | Dimension | ||

| L | W | L1 | ||

| ZJⅡ-3-80 | 0835820 | 420 | 40 | 80 |

| ZJⅡ-3-120 | 0835821 | 500 | 50 | 120 |

| ZJⅡ-4-80 | 0835822 | 500 | 40 | 80 |

| ZJⅡ-4-120 | 0835823 | 620 | 50 | 120 |

| Model | Code | Dimension |

| PZDL-A | 0836101 | subject to conductor spec and expansion section type |

| PZDL-B | 0836102 | |

| PZDT-A | 0836103 |

The single-pole sliding contact line is a conductive device used for powering mobile devices and has the following advantages:

I. Advantages of single-pole sliding contact line Structure Design

1 Conductor Cross-sectional area LARGE single-pole sliding contact line usually uses a single copper or aluminum conductor, cross-sectional area can be flexibly designed according to current demand, can carry high current load (up to thousands of amperes), suitable for large lifting machinery, mining equipment and other high power scenarios.

2. The structure is simple and compact

The conductor is in a single straight line, without complex components, and occupies a small installation space. It is particularly suitable for indoor and outdoor rail transportation systems with limited space.

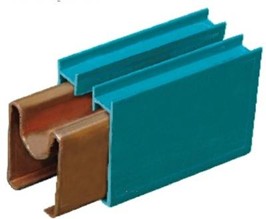

Lightweight design is convenient for transportation and installation, which can reduce construction costs.

3 Reliable insulation protection The conductor is wrapped with high strength insulation material (such as PVC, PE or special engineering plastic), which has dust-proof, water-proof and corrosion-proof performance, suitable for harsh industrial environment (such as high temperature, high humidity, dusty scene).

Ii. Electrical Performance Advantages of Single-pole Sliding contact Lines

1 HIGH electrical conductivity efficiency single-pole conductor low resistance, small electrical energy loss, stable electrical conductivity, can reduce heat and energy waste, improve system energy efficiency.

2. Excellent safety performance

The insulating shell can prevent people from directly touching the conductor and reduce the risk of electric shock.

The surface of the conductor is smooth, and the contact slider (collector) slides smoothly without generating electric sparks, making it suitable for flammable and explosive environments (explosion-proof design is required).

3 STRONG ANTI-INTERFERENCE ABILITY Single-pole structure reduces electromagnetic interference between multi-pole conductors, suitable for power supply of precision equipment with high requirements for signal stability.

Iii. Advantages of Installation and Maintenance of Single-pole Sliding Contact Lines

1. Easy and flexible installation

It supports various layouts such as straight lines, curves, and branches, and can flexibly adjust the direction according to the equipment's running track to adapt to complex working conditions.

The modular design makes component replacement convenient. During installation, it only needs to be fixed beside the bracket or track, without the need for complex debugging.

2. Low maintenance cost

The surface of the unipolar conductor wears evenly, the replacement cycle of the collector is long, and the maintenance workload is small.

The insulating housing is detachable, facilitating regular inspection of the conductor condition. During maintenance, there is no need to disassemble the sliding contact line as a whole.

3. Strong scalability

Current expansion can be achieved by parallel connection of multiple sliding contact lines, or by adding protective devices (such as protective covers) to meet higher safety requirements.

Support integration with intelligent monitoring systems (such as the installation of temperature sensors) to monitor the operating status in real time and issue early warnings of faults.

Fourth, the single-pole sliding contact line has a wide range of applicable scenarios

Heavy industry sector: Power supply for high-current equipment such as cranes and electric flatbed trucks in steel mills, shipyards, and mines.

Warehousing and logistics: Power supply systems for mobile equipment such as stackers and AGV carts in automated stereoscopic warehouses.

Municipal engineering: Scenarios that require flexible power supply, such as metro maintenance vehicles and tunnel construction machinery.

Light industry scenarios: such as low to medium current power supply for production line conveyor belts and mobile workbenches in workshops (aluminum conductors can be selected to reduce costs).

V. Economic Advantages of Single-pole Sliding Contact Line

1 Lower Initial INVESTMENT Compared with multi-pole sliding contact line or cable power supply system, single-pole sliding contact line is simpler in structure, more cost-effective in material cost and installation cost, especially suitable for long-distance power supply scenarios.

2 Low LONG-TERM operating cost Low energy consumption, less maintenance FEATURE CAN reduce the electricity expenditure and labor cost of enterprises, extend the service life of equipment.

Summary

Single-pole sliding contact lines have become one of the mainstream choices for power supply of mobile devices in the industrial field due to their advantages such as high load capacity, safety and reliability, convenient installation and maintenance, and strong environmental adaptability. In practical applications, copper conductors (with excellent electrical conductivity) or aluminum conductors (with low cost) can be selected based on current requirements, environmental conditions and budget, and corresponding protective accessories can be matched to further enhance system performance.