- Home

- >

- Products

- >

- Unipolar slide line

- >

Unipolar slide line

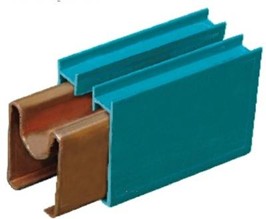

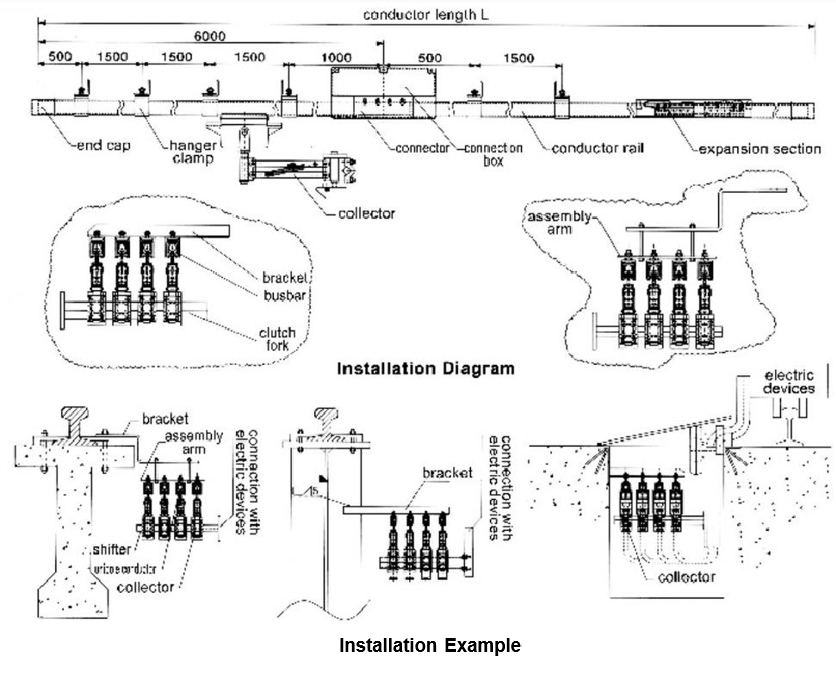

SJD unipole safety conductor can be any combination as needed,the aluminum conductor features speedy running, hi-amperage carrying and hi-temperature resistance.The inner upper side adopts cold welding and with stainless steel strip inlaid to strengthen the corrosion and wear resistance,service life more than 10 years.The insulation housing can be inten- sified if needed.

- Information

| ltem | Data |

| Breakdown Voltage | 20KV/min |

| IP | IP23 |

| Withstand Current | 20 times rated current,1s |

| Insulation Dielectric Strength | 3000VAC industrial frequency,1min,no breakdown and flashover |

| Insulation Resistance | 10MΩ |

| Working Votlage | AC:660V or DC:1000V |

| Fire Retardance | Bunsens burner,qualified,good fire-retardant |

| Collector Working Speed | V≤360m/min |

| Model | Code | Cross-section mm² | Rated Current A | Resistance Ω/km | Impedance Ω/km | Support Bracket |

| SJDL-130/150 | 0831010 | 130 | 150 | 24×32 | 0.2154 | 0.2154 |

| SJDL-160/250 | 0831011 | 160 | 250 | 0.1905 | 0.2195 | |

| SJDL-198/320 | 0831012 | 198 | 320 | 33×42 | 0.1333 | 0.1333 |

| SJDL-320/500 | 0831013 | 320 | 500 | 0.0952 | 0.1455 | |

| SJDL-400/630 | 0831014 | 400 | 630 | 0.0762 | 0.1338 | |

| SJDL-500/800 | 0831015 | 500 | 800 | 0.0609 | 0.1258 | |

| SJDL-700/1000 | 0831016 | 700 | 1000 | 0.0435 | 0.1184 | |

| SJDL-800/1250 | 0831017 | 800 | 1250 | 0.0381 | 0.0987 | |

| SJDL-1200/1600 | 0831018 | 1200 | 1600 | 52×65 | 0.0254 | 0.0904 |

| SJDL-1600/2000 | 0831019 | 1600 | 2000 | 0.0190 | 0.0889 | |

| SJDL-2000/2500 | 0831020 | 2000 | 2500 | 0.0152 | 0.0881 |

| Model | Code | Cross-section mm² | Rated Current A | Resistance Ω/km | Impedance Ω/km | Support Bracket |

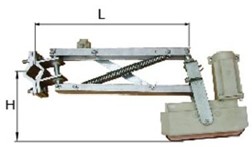

| SJDT-160/500 | 0832021 | 160 | 500 | 20×26 | 0.1161 | 0.1594 |

| SJDT-250/700 | 0832022 | 250 | 700 | 0.0743 | 0.1327 | |

| SJDT-320/1000 | 0832023 | 320 | 1000 | 32×42 | 0.0580 | 0.1244 |

| SJDT-400/1250 | 0832024 | 400 | 1250 | 0.0464 | 0.1194 | |

| SJDT-500/1600 | 0832025 | 500 | 1600 | 0.0372 | 0.1161 | |

| SJDT-700/2000 | 0832026 | 700 | 2000 | 0.0265 | 0.1132 |

| Model | Code | Cross-section mm² | Rated Current A | Resistance Ω/km | Impedance Ω/km | Support Bracket |

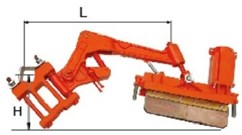

| SJDT-L-38.4/150 | 0833030 | 38.4 | 150 | 20×26 | 0.485 | 0.489 |

| SJDT-L-57.6/250 | 0833031 | 57.6 | 250 | 0.323 | 0.328 | |

| SJDT-L-75.6/320 | 0833032 | 75.6 | 320 | 32×42 | 0.246 | 0.250 |

| SJDT-L-140.4/500 | 0833033 | 140.4 | 500 | 0.124 | 0.128 |

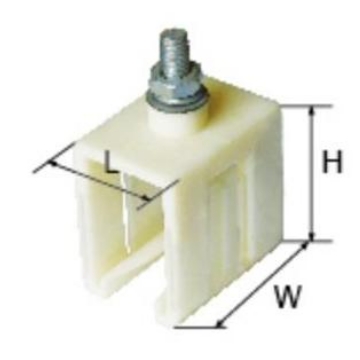

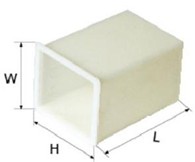

| Model | Code | Dimension | Weight KG | ||

| L | H | W | |||

| XDT-1 | 0835211 | 27 | 43 | 40 | 0.050 |

| XDT-2 | 0835212 | 31 | 46 | 55 | 0.075 |

| XDT-3 | 0835213 | 43 | 61 | 60 | 0.100 |

| XDT-4 | 0835214 | 63 | 88 | 76 | 0.150 |

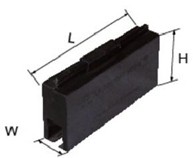

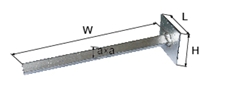

| Model | Code | Dimension | Weight KG | ||

| L | H | W | |||

| LJ-1 | 0835310 | 160 | 60 | 25 | 0.08 |

| LJ-2 | 0835311 | 240 | 90 | 45 | 0.20 |

| LJ-3 | 0835312 | 260 | 150 | 70 | 0.50 |

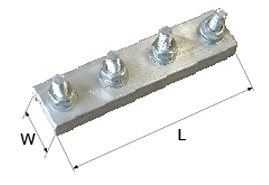

| Model | Code | Dimension | Weight KG | |

| L | W | |||

| DL-1 | 0835511 | 105 | 25 | 0.18 |

| DL-2 | 0835512 | 152 | 32 | 0.30 |

| DL-3 | 0835513 | 170 | 63 | 0.50 |

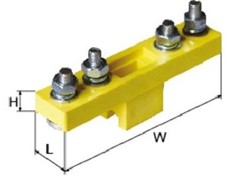

| Model | Code | Dimension | ||

| L | H | W | ||

| DM-1 | 0835331 | 78 | 35 | 42 |

| DM-2 | 0835332 | 70 | 53 | 43 |

| DM-3 | 0835333 | 80 | 80 | 65 |

| Model | Code | Dimension | |||

| L | axa | H | W | ||

| BC-1 | 0835611 | 100 | 25×25 | 100 | 330 |

| BC-2 | 0835612 | 100 | 25×25 | 100 | 410 |

| Model | Code | Dimension | ||

| L | H | W | ||

| JX-1 | 0835711 | 26.5 | 13 | 104.5 |

| JX-2 | 0835712 | 38 | 20 | 161 |

| JX-3 | 0835713 | 57 | 20 | 180 |

| Model | Code | Dimension | |

| L | H | ||

| SJDA-100 | S0835010 | 200 | 60 |

| Model | Code | Dimension | |

| L | H | ||

| SJDA-150 | 0835020 | 300 | 150 |

| Model | Code | Dimension | |

| L | H | ||

| SJDA-250 | 0835030 | 400 | 130 |

| Model | Code | Dimension | |

| L | H | ||

| SJDA-400 | 0835040 | 370 | 150 |

| Model | Code | Dimension | |

| L | H | ||

| SJDA-500 | 0835050 | 400 | 200 |

| Model | Code | Dimension | ||

| L | W | L1 | ||

| ZJI-3-80 | 0835811 | 370 | 40 | 80 |

| ZJI-3-120 | 0835812 | 380 | 50 | 120 |

| ZJI-4-80 | 0835813 | 450 | 40 | 80 |

| ZJI-4-120 | 0835814 | 500 | 50 | 120 |

| Model | Code | Dimension | ||

| L | W | L1 | ||

| ZJⅡ-3-80 | 0835820 | 420 | 40 | 80 |

| ZJⅡ-3-120 | 0835821 | 500 | 50 | 120 |

| ZJⅡ-4-80 | 0835822 | 500 | 40 | 80 |

| ZJⅡ-4-120 | 0835823 | 620 | 50 | 120 |

| Model | Code | Dimension |

| PZDL-A | 0836101 | subject to conductor spec and expansion section type |

| PZDL-B | 0836102 | |

| PZDT-A | 0836103 |

Single-pole sliding contact line (also known as single-pole safety sliding contact line or single-pole power supply sliding contact line) is a system used for power supply to mobile equipment (such as cranes, electric hoists, automated production lines, etc.), and it has the following advantages:

The single-pole sliding contact line is safe and reliable

· Good insulation protection: The casing is made of PVC or engineering plastic, with a high protection level (usually IP23 or above), preventing the risk of electric shock.

· Dust-proof and moisture-proof: The closed design reduces the intrusion of dust and moisture, making it suitable for harsh environments such as factories and ports.

· Short-circuit prevention: Single-pole independent power supply, which is safer than bare wires and avoids interphase short circuits.

2. The installation and maintenance of the single-pole sliding contact line are simple and convenient

· Modular design: It can be installed in sections, with flexible length adjustment to meet the requirements of different spans.

· Maintenance-free: The collector has stable contact with the guide rail, with minimal wear, and requires no frequent maintenance over long-term use.

· Easy to replace: When a single pole is damaged, only the corresponding section needs to be replaced, which does not affect the overall system operation.

3. The single-pole sliding contact line is highly efficient and energy-saving

· Low impedance: High-quality conductive materials (such as copper or aluminum alloy) reduce resistance and minimize power loss.

· Stable voltage: Good contact to avoid voltage fluctuations and ensure the stable operation of the equipment.

4. The single-pole sliding contact line has strong adaptability

· Corrosion-resistant: Available in aluminum alloy or stainless steel, suitable for humid, chemical and other corrosive environments.

· Resistance to high and low temperatures: Wide operating temperature range (-30℃ to 120℃), suitable for different climatic conditions.

· Resistance to mechanical shock: The sturdy casing protects the internal conductors from external force damage.

5. The single-pole sliding contact line is economical and practical

· Long service life: The wear-resistant collector and anti-oxidation guide rails can have a service life of more than 10 years.

· Low comprehensive cost: Compared with cable drag chains or bare wire sliding contact lines, the long-term usage and maintenance costs are lower.

6. The single-pole sliding contact line is flexibly configured

· Multi-stage current selection: from 100A to over 1000A, meeting the power requirements of different devices.

· Scalability: Supports multi-pole combination (such as 3-pole +PE), suitable for three-phase power supply systems.

The applicable scenarios of the single-pole sliding contact line

· Lifting equipment: bridge cranes, gantry cranes, overhead cranes, etc.

· Automated production lines: conveyors, AGV carts, automated warehousing systems.

· Other mobile power supply: amusement facilities, stage equipment, wharf loading and unloading equipment, etc.

Summary

Single-pole sliding contact lines stand out in terms of safety, durability, energy efficiency and ease of installation. They are an ideal choice for power supply to mobile devices, especially suitable for industrial environments that require stable power transmission.