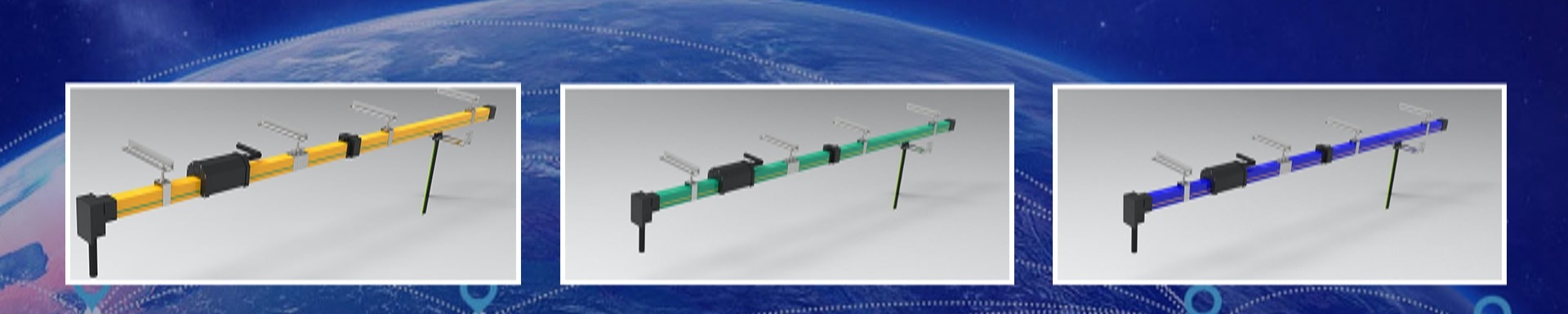

rigid sliding contact line

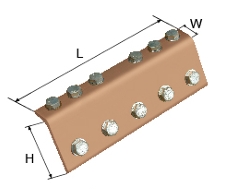

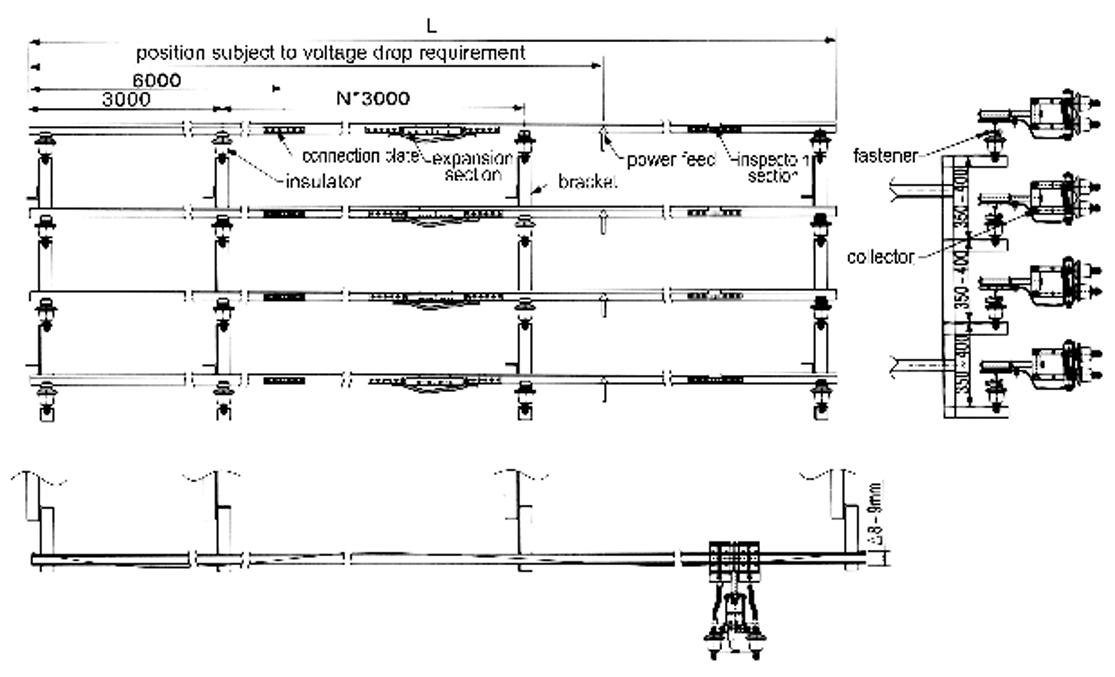

SJG copperhead conductor system uses oxygen-free copper as conductor rail,figured steel or aluminum as support bracket,formation by assembling or combination.It is widely used in severe environment of hi-temperature,moist,dust, hi-voltage,hi-amperage like casting.SKGL steel aluminum cooperhead system has below advantages:light,good conduc- tivity.simple structure and low cost.

- Information

| ltem | Data |

| Housing IP | Short-time condensation allowable |

| Temperatiure | -45℃~+150℃ |

| Current Withstand | 10 times rated current,1s |

| Dielectric Strength | 10000vAC industrial frequency,1min,no breakdown and flashover |

| Insulation Resistance | IV级 |

| Pollution Grade | R>10MΩ |

| Working Voltage | AC:600V-6000V (50~60Hz) |

| Collector Working Speed | U≤360 m/min |

| Model | Code | Cross-section mm² | Rated Current A | Resistance Ω/km | Impedance Ω/km | Support Bracket |

| SJGP-85/400 | 0851101 | 85 | 400 | 0.2118 | 0.2896 | 20×40×60 |

| SJGP-110/500 | 0851102 | 110 | 500 | 0.1636 | 0.2545 | |

| SJGP-170/630 | 0851103 | 170 | 630 | 0.1059 | 0.2098 | |

| SJGP-240/800 | 0851104 | 240 | 800 | 0.0750 | 0.1888 | |

| SJGP-320/1000 | 0851105 | 320 | 1000 | 0.0563 | 0.1730 | 30×50×80 |

| SJGP-420/1250 | 0851106 | 420 | 1250 | 0.0429 | 0.1653 | |

| SJGP-550/1600 | 0851107 | 550 | 1600 | 0.0327 | 0.1541 | |

| SJGP-700/2000 | 0851108 | 700 | 2000 | 0.0257 | 0.1424 | |

| SJGP-170I/1250 | 0851109 | 340 | 1250 | 0.0529 | 0.1533 | 54×50×80 |

| SJGP-240I/1600 | 0851110 | 480 | 1600 | 0.0375 | 0.1451 | |

| SJGP-320Ⅱ/2000 | 0851111 | 640 | 2000 | 0.0282 | 0.1347 | |

| SJGP-420Ⅱ/2500 | 0851112 | 840 | 2500 | 0.0215 | 0.1286 | |

| SJGP-550Ⅱ/3150 | 0851113 | 1100 | 3150 | 0.0164 | 0.1068 | |

| SJGP-700Ⅱ/4000 | 0851114 | 1400 | 1400 | 0.0129 | 0.1060 |

| Model | Code | Cross-section mm² | Rated Current A | Resistance Ω/km | Impedance Ω/km | Support Bracket |

| SJGF-85/400 | 0850100 | 85 | 400 | 0.2118 | 0.2896 | 30×35 |

| SJHGF-100/500 | 0852101 | 100 | 500 | 0.180 | 0.2594 | |

| SJGF-150/630 | 0852102 | 150 | 630 | 0.120 | 0.2198 | |

| SJGF-200/800 | 0852103 | 200 | 800 | 0.090 | 0.1957 | 35×45 |

| SJGF-300/1000 | 0852104 | 300 | 1000 | 0.060 | 0.1741 | |

| SJGF-400/1250 | 0852105 | 400 | 1250 | 0.045 | 0.1640 | |

| SJGF-500/1600 | 0852106 | 500 | 1600 | 0.036 | 0.1556 | 40×50 |

| SJGF-650/2000 | 0852107 | 650 | 2000 | 0.028 | 0.1466 | |

| SJGF-800/2500 | 0852108 | 800 | 2500 | 0.023 | 0.1416 | |

| SJGF-1000/3150 | 0852109 | 1000 | 3150 | 0.018 | 0.1261 | |

| SJGF-1200/3500 | 0852110 | 1200 | 3500 | 0.015 | 0.1173 | 40×58 |

| SJGF-1400/4000 | 0852111 | 1400 | 4000 | 0.013 | 0.1112 |

| Model | Code | Cross-section mm² | Rated Current A | Resistance Ω/km | Impedance Ω/km | Aluminum bracket track dimension |

| SJGL-198/320 | 0853100 | 198 | 320 | 0.1333 | 0.1362 | 18×36 |

| SJHGL-320/500 | 0853101 | 320 | 500 | 0.0952 | 0.1455 | 24×36 |

| SJGL-400/700 | 0853102 | 400 | 700 | 0.0609 | 0.1258 | 32×36 |

| SJGL-700/1000 | 0853103 | 700 | 1000 | 0.0435 | 0.1184 | 29×46 |

| SJGL-1200/1600 | 0853104 | 1200 | 1600 | 0.0254 | 0.0904 | 44×56 |

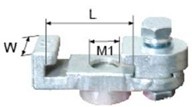

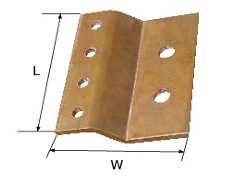

| Model | Code | Dimension | ||

| L | M1 | W | ||

| GD-35 | 0852201 | 36 | 12 | 30 |

| GD-45 | 0852202 | 47 | 16 | 40 |

| GD-50 | 0852203 | 52 | 16 | 40 |

| Model | Code | Dimension | ||

| L | L1 | W | ||

| GD I-35 | 0852204 | 36 | 69 | 40 |

| GD I-45 | 0852205 | 47 | 90 | 45 |

| GD I-50 | 0852206 | 52 | 90 | 45 |

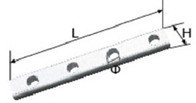

| Model | Code | Dimension | ||

| L | Φ | W | ||

| LBF-100 | 0852301 | 190 | 11 | 31 |

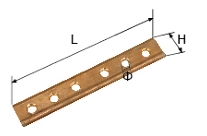

| Model | Code | Dimension | ||

| L | Φ | W | ||

| LBF-100 | 0852302 | 90 | 8.5 | 24 |

| LBF-300 | 0852303 | 210 | 11 | 31 |

| LBF-600 | 0852304 | 210 | 11 | 35 |

| LBF-800 | 0852305 | 210 | 11 | 38 |

| Model | Code | Dimension | ||

| L | H | W | ||

| GX-1 | 0852511 | 200 | 80 | 20 |

| Model | Code | Dimension | |

| L | W | ||

| GX-2 | 0852512 | 90 | 88 |

| Model | Code | Dimension | |

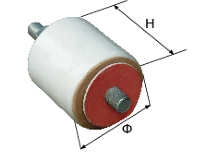

| H | Φ | ||

| JY-1 | 0852611 | 80 | 74 |

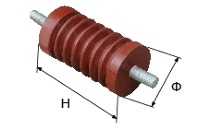

| Model | Code | Dimension | |

| H | Φ | ||

| JY-2 | 0852612 | 130 | 70 |

| Model | Code | Cross-section mm² | Rated Current A | Resistance Ω/km | Impedance Ω/km |

| SJGZ-800/2500 | 0854101 | 800 | 2500 | 0.023 | 0.1079 |

| SJGZ-1000/3150 | 0854102 | 1000 | 3150 | 0.018 | 0.1031 |

| SJGZ-1200/3500 | 0854103 | 1200 | 3500 | 0.015 | 0.1004 |

| SJGZ-1400/4000 | 0854104 | 1400 | 4000 | 0.013 | 0.0972 |

| SJGZ-1800/5000 | 0854105 | 1800 | 5000 | 0.010 | 0.0890 |

| Model | Code | Cross-section mm² | Rated Current A | Resistance Ω/km | Impedance Ω/km | Support Bracket |

| SJGQ-85/100 | 0855101 | 85 | 400 | 0.2118 | 0.2896 | 30×40 |

| SJGQ-110/500 | 0855102 | 110 | 500 | 0.1636 | 0.2545 | |

| SJGQ-170/630 | 0855103 | 170 | 630 | 0.1059 | 0.2098 | |

| SJGQ-240/800 | 0855104 | 240 | 800 | 0.0750 | 0.1888 | |

| SJGQ-320/1000 | 0855105 | 320 | 1000 | 0.0563 | 0.1730 | 40×45 |

| SJGQ-420/1250 | 0855106 | 420 | 1250 | 0.0429 | 0.1653 | |

| SJGQ-550/1600 | 0855107 | 550 | 1600 | 0.0327 | 0.1541 | |

| SJGQ-700/2000 | 0855108 | 700 | 2000 | 0.0210 | 0.1421 |

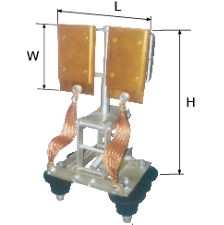

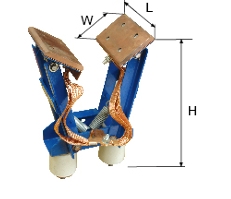

| Model | Code | Dimension | ||

| L | H | W | ||

| SJG-A/3750×2 | 0856101 | 250 | 500 | 150 |

| Model | Code | Dimension | ||

| L | H | W | ||

| SJG-B/3750×2 | 0856102 | 150 | 450 | 100 |

Steel body sliding contact lines (also known as rigid sliding contact lines or steel body conductive rails) are conductive systems used to supply power to mobile equipment such as cranes, electric hoists, conveyors, etc. Compared with traditional cables or flexible sliding contact lines, steel sliding contact lines have the following advantages:

The steel body sliding contact line has high electrical conductivity

Copper or copper-aluminum alloy is usually used as the conductor, which has a high electrical conductivity and low power loss, making it suitable for high-current transmission (up to several thousand amperes).

Low resistance, reduced heat generation, and improved energy efficiency.

2. The steel body sliding contact line has high mechanical strength

The rigid structure design ensures strong resistance to impact and vibration, and is not prone to deformation or breakage.

It is suitable for harsh industrial environments (such as high-temperature, high-humidity, and dusty occasions, etc.).

3. The steel body sliding contact line has a long service life and low maintenance

It has good wear resistance. The collector (brush) and the sliding contact line have stable contact, with less wear and a long service life.

· No frequent replacement or adjustment is required, and the maintenance cost is low.

4. The steel body sliding contact line is easy to install and has a stable structure

Modular design, simple installation, and can be arranged horizontally or vertically.

The bracket is firmly fixed and not prone to shaking, ensuring the stability of power supply.

5. Steel body sliding contact lines have strong adaptability

It can be used in various indoor and outdoor environments and is corrosion-resistant (some models are made of stainless steel or have anti-corrosion coatings).

It is suitable for high-speed and heavy-duty equipment (such as port cranes and automated production lines).

6. The steel body sliding contact line has high safety

The casing is usually made of insulating materials (such as PVC or engineering plastics), with a high protection grade (IP23 or above), and is resistant to electric shock, dust and water.

· No exposed wires, reducing the risk of short circuits.

7. Steel body sliding contact lines are energy-saving and environmentally friendly

The low-impedance design reduces power waste and meets the requirements of green energy.

The material is recyclable and has good environmental friendliness.

8. The steel body sliding contact line can be customized flexibly

The length, current capacity (such as 100A to 5000A) and voltage level (commonly AC 380V to 1000V) can be customized according to requirements.

Notes:

It is necessary to regularly check the wear of the collector and the cleanliness of the sliding contact line to avoid dust accumulation affecting the electrical conductivity.

In conclusion, steel sliding contact lines have become the preferred solution for mobile power supply in heavy industry due to their high reliability, durability and efficient power supply.

Rigid sliding contact lines are a type of power transmission device used in mobile equipment such as cranes and overhead cranes, and they have the following significant advantages:

1. The rigid body sliding contact line has a solid and durable structure with strong load-bearing capacity

· Rigid structure design: Copper or aluminum bars are used as the conductive main body, and the exterior is protected by a high-strength aluminum alloy or stainless steel shell. The overall structure is highly rigid, with excellent impact and vibration resistance, and can adapt to frequent movement and harsh working conditions in heavy industrial environments (such as high temperatures, dust, corrosive gases, etc.).

· Stable high current transmission: The conductor has a large cross-sectional area (up to several hundred square millimeters), capable of withstanding currents of up to several thousand amperes. It features strong power transmission stability and is less likely to cause issues such as overheating or power outages due to current overload or poor contact. It is suitable for the power supply requirements of high-power equipment.

Second, the rigid sliding contact line is safe and reliable with excellent protective performance

· Closed protection design: The conductive busbar is completely enclosed within the casing, avoiding direct exposure to the external environment. It can prevent impurities such as dust, water vapor, and oil stains from entering, reducing the risk of short circuits. At the same time, it minimizes the possibility of personnel coming into contact with the conductive body, enhancing operational safety.

· Excellent insulation performance: The casing is made of insulating materials (such as epoxy resin, high-strength plastic, etc.), and there is a reliable insulating layer between the internal conductor and the casing, with a high insulation grade. This can effectively prevent electric leakage accidents and is especially suitable for industrial environments with high humidity, dust or corrosive media.

· Strong arc resistance: The conductor surface is smooth, the contact is tight, and the connection points are treated with special processes (such as tin plating or tin plating), which can reduce the generation of arcs, extend the service life, and lower the risk of fire.

Third, the rigid sliding contact line is easy to install and maintain, and has strong adaptability

· Modular installation: It adopts a segmented modular design, which can be flexibly combined according to the length of the equipment's running track. The installation process is simple and fast, without the need for complex on-site processing. It also supports various installation methods such as horizontal, vertical, and curved, meeting the layout requirements of different equipment.

· Low maintenance cost: The rigid structure is not prone to deformation, the conductor wears less, and the daily maintenance workload is small. It is only necessary to regularly check the tightness of the connection points and the integrity of the casing. There is no need to frequently replace parts, which reduces maintenance costs and downtime.

· Wide environmental adaptability: It can operate stably within a wide temperature range of -30 ℃ to +120℃, with excellent resistance to high and low temperatures. At the same time, it is resistant to aging and ultraviolet rays, making it suitable for outdoor open-air environments or high-temperature workshops and other special environments.

Fourth, the rigid sliding contact line has excellent electrical conductivity and low energy loss

· High-conductivity conductors: Using red copper or high-purity aluminum as conductors, they have high conductivity (copper conductivity ≥100% IACS, aluminum conductivity ≥61% IACS), low resistance, and low energy loss during power transmission, which can improve the operational efficiency of equipment and reduce energy consumption costs.

· High contact reliability: The collector (receiver) is in close contact with the sliding contact line conductor. It adopts spring pressure or rolling contact methods to ensure good electrical continuity even under high-speed movement or vibration conditions of the equipment, avoiding power failure or electric spark problems caused by poor contact.

Five, rigid sliding contact lines have a long service life and high comprehensive cost performance

· Wear-resistant and corrosion-resistant: The surface of the conductor can be further enhanced in terms of wear resistance and corrosion resistance through processes such as nickel plating and silver plating. The casing is made of corrosion-resistant materials (such as stainless steel or aluminum alloy with anodic oxidation treatment), and the overall service life can reach over 10 years, which is much longer than that of ordinary flexible sliding contact lines or cable power supply systems.

· Comprehensive cost advantage: Although the initial investment cost is slightly higher than that of some flexible sliding contact lines, due to its long service life, low maintenance and high reliability, the comprehensive cost during long-term use (including maintenance, replacement, energy consumption, etc.) is lower, making it particularly suitable for large industrial equipment or scenarios that require continuous operation for a long time.

Vi. Other Advantages of Rigid Sliding contact Lines

· Flexible and aesthetically pleasing layout: It can be customized according to the factory structure or the operation trajectory of the equipment, installed above or on the side of the equipment, without occupying ground space, making the workshop layout neater and more beautiful.

· Supports high-speed movement: With low sliding contact resistance, it can adapt to the high-speed operation of equipment (up to over 100 meters per minute), meeting the modern industrial demand for efficient production.

·

The applicable scenarios of rigid sliding contact lines

Rigid sliding contact lines are widely used in the power supply systems of mobile equipment such as cranes, overhead cranes, electric hoists, and automated production lines in industries like metallurgy, mining, mechanical manufacturing, warehousing and logistics, and port terminals. They are particularly suitable for heavy industrial scenarios with high requirements for reliability, safety, and load-bearing capacity.