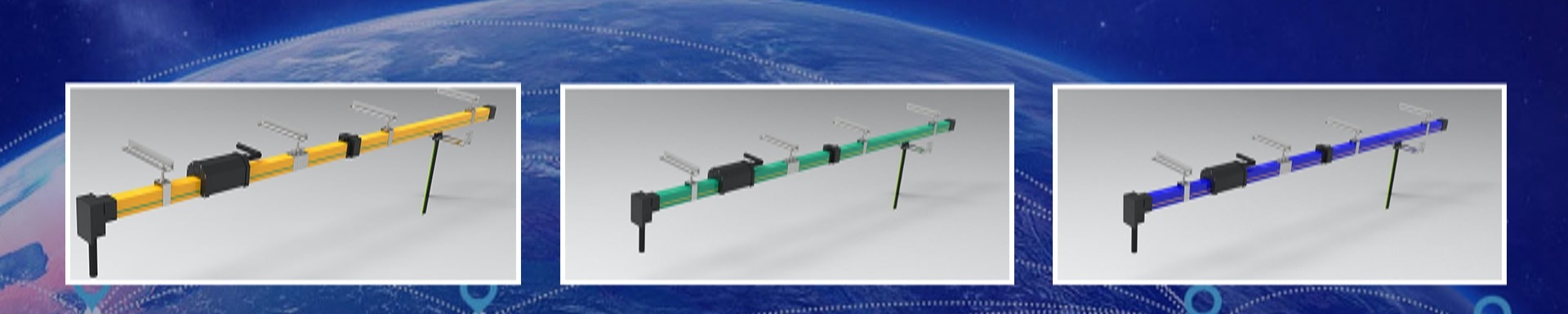

High-temperature rigid sliding contact line

Product Overview of High-temperature Rigid Sliding Contact Line (High-temperature Rigid Sliding Conductor) :

High-temperature steel sliding conductors are composed of copper conductors and steel structural skeletons, and they come in two structural types: combined and composite. They are supported by high-strength special insulators and installed or welded onto the brackets of the track beams, thereby forming a mobile power supply system that feeds to various lifting machinery and equipment. High-temperature steel sliding conductors are a type of sliding power transmission device with a wide range of applications. They can be widely used in environments with high temperatures, high humidity, high voltage, strong corrosion, and much dust, such as steelmaking, metallurgy, high voltage, strong corrosion, and much dust. Such as steelmaking, metallurgy and chemical engineering, docks and other industries.

- Information

High-temperature rigid sliding contact line (high-temperature rigid sliding conductor)

(1) Product Overview of High-temperature Rigid Sliding Contact Line (High-temperature Rigid Sliding Conductor) :

High-temperature steel sliding conductors are composed of copper conductors and steel structural skeletons, and they come in two structural types: combined and composite. They are supported by high-strength special insulators and installed or welded onto the brackets of the track beams, thereby forming a mobile power supply system that feeds to various lifting machinery and equipment. High-temperature steel sliding conductors are a type of sliding power transmission device with a wide range of applications. They can be widely used in environments with high temperatures, high humidity, high voltage, strong corrosion, and much dust, such as steelmaking, metallurgy, high voltage, strong corrosion, and much dust. Such as steelmaking, metallurgy and chemical engineering, docks and other industries.

(2) Product Features of High-temperature rigid sliding contact Line (high-temperature rigid sliding wire) :

1. It has excellent contact performance, no arc pulling phenomenon, no power interruption failure, and reliable operation.

2. It can be applied in harsh environments such as high temperature, high humidity, high voltage, strong corrosion and much dust.

3. It features high mechanical strength, good rigidity, and is not prone to bending or deformation. It can withstand large short-circuit impulse currents without causing malfunctions.

4. The use of copper conductors or copper-aluminum profiles with lower resistivity can significantly reduce the power loss of the wires themselves.

5. Copper conductors have a large current-carrying capacity, with the maximum reaching over 3000A.

After adding auxiliary cables, the impedance of the wire can be reduced several times, allowing for the formation of low-impedance sliding wires, which are more widely used.

7. The wiring can be diversified and can be slid on the top, bottom or side.

8. The high-temperature steel sliding wire has a large heat dissipation area, low temperature rise and a long service life.

9. It has a simple structure and is easy to install, and can be divided into three types: top-pressing type, side-pressing type and bottom-pressing type.

10. Maintenance and replacement are convenient, prompt, time-saving and labor-saving.

(3) Application environment of high-temperature rigid sliding contact line (high-temperature rigid sliding wire) :

The altitude does not exceed 2,000 meters

The relative humidity of the ambient air shall not exceed 95%, and the ambient temperature for use shall be less than 150℃