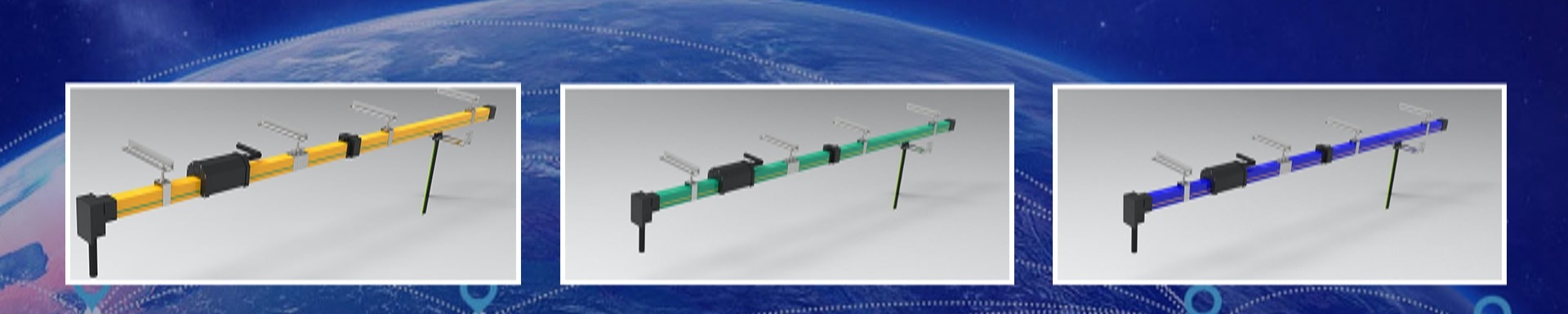

Seamless sliding line

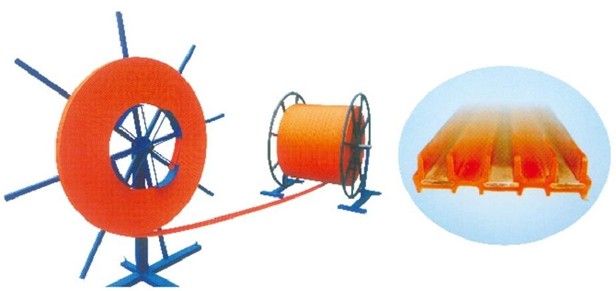

SJB High-Tro-Reel conductor system takes oxygen-free copper as conductor rail,uses PVC housing and features easy installation,high speed,stable running and compact structure.It is widely used in small and middle size cranes and unmanned factories,stereoscopic warehouse logistic,etc.

- Information

| ltem | Data |

| Housing Breakdown Voltage | >25KV/min |

| Housing IP | IP23 |

| Current Withstand | 10 times rated current,1s |

| Dielectric Strength | 3000vAC industrial frequency,1min,no breakdown |

| Insulation Resistance | R>10MΩ |

| Pollution Grade | IV(general conductive dust &condensation) |

| Working Voltage | DC:1000V or AC:600V |

| Fire Retardant | Bunsens burner,qualified,good fire-retardant |

| Collector Working Speed | V≤600m/min |

| Model | Code | Cross-section mm² | Rated Current A | Resistance Ω/km | Impedance Ω/km |

| SJB-3-10/50 | 0861101 | 10 | 50 | 1.350 | 1.422 |

| SJB-3-16/80 | 0861102 | 16 | 80 | 0.843 | 0.892 |

| SJB-3-25/125 | 0861103 | 25 | 125 | 0.540 | 0.578 |

| SJB-4-10/50 | 0861104 | 10 | 50 | 1.800 | 1.896 |

| SJB-4-16/80 | 0861105 | 16 | 80 | 1.125 | 1.189 |

| SJB-4-25/125 | 0861106 | 25 | 125 | 0.720 | 0.770 |

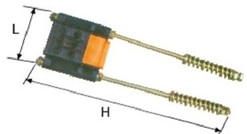

| Model | Code | Dimension | |

| L | H | ||

| ZJ-1 | 0862101 | 115 | 370 |

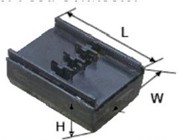

| Model | Code | Dimension | ||

| L | H | W | ||

| XD-80 | 0862102 | 62 | 25 | 42 |

| Model | Code | Dimension | |

| L | H | ||

| SJS-1 | 0862103 | 140 | 90 |

| Model | Code | Dimension | ||

| L | H | W | ||

| LJG-1 | 0862104 | 120 | 50 | 90 |

Seamless sliding contact line (also known as seamless sliding contact line or continuous sliding contact line) is a power supply system that adopts an integral conductor design. Compared with the traditional segmented sliding contact line, it has the following significant advantages:

The seamless sliding contact line provides more stable power supply and eliminates the risk of power outages

· Seamless design: The conductor is continuous without any splicing points, avoiding problems such as power failure and sparks caused by loose, oxidized or worn joints.

· Smooth current transmission: Reduce voltage fluctuations to ensure more stable operation of mobile devices such as cranes and automated trolleys.

2. The seamless sliding contact line has an extremely long service life and low maintenance cost

· No mechanical wear points: The joints of traditional sliding contact lines are prone to wear, while the seamless design significantly extends the service life (up to 15 years or more).

· Strong corrosion resistance: It adopts high-purity copper or aluminum alloy conductors, which are anti-oxidation and anti-rust, making it suitable for humid and dusty environments.

3. Seamless sliding contact lines are suitable for high-speed and high-frequency moving devices

· Low impedance: The conductor is continuous with low resistance, making it suitable for equipment with high current (100A to 2000A) and high-frequency reciprocating motion.

· No shock or vibration: The collector slides on a smooth guide rail without joint jolts, reducing mechanical wear and noise.

4. The seamless sliding contact line is easy to install and highly flexible

· Flexible design: Some seamless sliding contact lines support installation on arc-shaped or curved tracks, suitable for complex layouts.

· No frequent connection required: Traditional sliding contact lines need a joint every 6 to 12 meters, while seamless sliding contact lines can be laid over long distances (such as 50 to 100 meters) at one time.

5. Seamless sliding contact lines offer higher safety

· Arc and short circuit prevention: No joints mean no risk of poor contact, reducing fire hazards.

· Fully enclosed structure: Some models adopt a protection level of IP54 or above, which is dust-proof, water-proof and resistant to foreign object intrusion.

6. Seamless sliding contact lines are energy-saving and highly efficient

· Excellent electrical conductivity: Copper conductors have a low resistivity and low power loss, making them more energy-efficient than traditional sliding contact lines.

· Reduce voltage drop: Suitable for long-distance power supply (such as large factories, logistics warehouses).

The application scenarios of seamless sliding contact lines

· High-speed cranes: metallurgical cranes, port container cranes, etc.

· Automated logistics system: AGV carts, automated warehouse conveyor lines.

· Precision equipment: semiconductor production lines, precision machine tools and other occasions with high requirements for current stability.

Summary

The seamless sliding contact line, with its features of no joints, long service life, high stability and low maintenance, is particularly suitable for industrial scenarios requiring high-speed, heavy-load and long-distance power supply. It is an ideal choice for enhancing equipment reliability and production efficiency.

The seamless sliding contact line is a power supply device that eliminates the joint gaps of traditional sliding contact lines through a special process. Its core advantages lie in the continuity of electrical conductivity, safety and reliability, and maintenance-free characteristics, making it particularly suitable for scenarios with extremely high requirements for power supply stability. The following are its main advantages:

I. Core Advantages of Seamless Structure

1. Excellent electrical conductivity continuity

The conductors (copper or aluminum) are made into seamless long rails through welding or integral extrusion processes, completely eliminating the joint gaps of traditional sliding contact lines (each section of traditional sliding contact lines is about 6 meters and expansion joints need to be reserved), avoiding the generation of electric sparks, poor contact or power outages when the collector slides over the joint, ensuring stable power supply throughout the process without fluctuations.

It is particularly suitable for high-speed mobile equipment (such as cranes with a running speed > 60m/min and automated logistics carts) and precision loads (such as semiconductor production lines and medical equipment), to prevent product scrapping or equipment failure caused by power outages.

It has excellent anti-vibration and thermal expansion performance

Seamless structures reduce mechanical weak points, can withstand vibration and shock during equipment operation, and avoid poor contact caused by loose joints.

The conductor adopts a temperature compensation design (such as reserving expansion allowance or using elastic materials), which can adapt to the thermal expansion and contraction (-30℃ to 80℃) caused by changes in environmental temperature, avoiding the deformation or cracking of traditional joints due to expansion and compression or contraction.

Second, the safety and protection performance of the seamless sliding contact line has been upgraded

Low-risk explosion-proof design

The seamless structure reduces the possibility of electric sparks. When paired with a fully enclosed insulating housing (such as flame-retardant PVC or aluminum alloy protective covers), it can further suppress the leakage of electric arcs, meeting the explosion-proof requirements of flammable and explosive environments (such as the chemical and oil and gas industries) (compliant with explosion-proof standards such as ATEX).

It has strong anti-corrosion and dust-proof capabilities

The surface of the conductor can be tin-plated or nickel-plated to enhance its oxidation resistance and corrosion resistance, making it suitable for high humidity, salt spray or acid spray environments (such as coastal factories and electroplating workshops).

The insulating housing adopts seamless splicing technology, with a protection level up to IP65, effectively preventing dust and liquid from entering, reducing the risk of conductor corrosion and short circuits.

Third, the seamless sliding contact line features maintenance-free operation and long service life

It requires almost no maintenance

It eliminates the mechanical wear and oxidation problems of traditional joints, making the contact between the collector and the conductor more uniform, reducing the wear rate by more than 50%, and significantly extending the service life of the collector and the conductor (the lifespan of the conductor can reach over 10 years).

There is no need to regularly tighten the joints or replace worn parts, saving labor costs. It is especially suitable for high-altitude or difficult-to-maintain scenarios (such as sliding contact lines on the top of large factories).

2. Reduce downtime losses

The joints of traditional sliding contact lines are prone to poor contact due to dust accumulation or oxidation and need to be cleaned regularly. The seamless design completely resolves this issue, reducing the downtime of equipment caused by power supply failures and enhancing production efficiency.

Iv. Advantages of Seamless Sliding Contact Line Installation and Adaptation

1. Efficient and flexible installation

It supports ultra-long distance single-section installation (up to several hundred meters), reducing the number of brackets and installation nodes, and the construction efficiency is increased by more than 30% compared with traditional sliding contact lines.

◦ Customized curved sections (such as arcs, S-shaped) can be made according to the shape of the track to adapt to complex motion trajectories (such as circular production lines, rotating cranes), without the need for additional joint accessories.

2. Compatible with various power supply requirements

Single-pole or multi-pole structures are available: single-pole is suitable for high-current scenarios (such as above 2000A), while multi-pole (2 to 12 poles) can integrate three-phase power supply, neutral wire, and ground wire to meet the power supply requirements of multiple circuits.

It is compatible with various types of collectors (such as carbon brush type and alloy roller type), and the optimal configuration can be selected according to the operating speed of the equipment (low speed to high speed) and the environment.

V. Application Scenarios and Economy of Seamless Sliding Contact Lines

The first choice for high-end industrial scenarios

◦ Precision manufacturing: Automated production lines in the semiconductor, electronics, and pharmaceutical industries require zero power supply interruption.

High-speed lifting equipment: port cranes, high-speed railway maintenance equipment (operating speed > 100m/min), power supply fluctuations at the joints need to be avoided.

◦ Harsh environments: Nuclear power plants, chemical workshops, metallurgical plants and other scenarios with extremely high requirements for safety and maintenance.

2. The long-term cost advantage is significant

The initial investment is higher than that of traditional sliding contact lines, but the full life cycle cost is low: the maintenance-free feature reduces labor and accessory costs, and the high conductivity (low resistance) can lower energy consumption. The overall cost is 20% to 30% lower than that of traditional solutions.

Summary

The seamless sliding contact line fundamentally solves the pain points of traditional sliding contact lines, such as poor contact and frequent maintenance, by eliminating physical seams, and has become the ultimate solution for high-reliability and high-security scenarios. Its core value lies in "zero-fault power supply", which is particularly suitable for industries that are sensitive to continuous production, equipment safety and maintenance costs. When making a selection, it is necessary to pay attention to customizing the design of seamless tracks and temperature compensation devices based on current requirements (copper conductors are preferred for high currents), ambient temperature and installation length to fully leverage their performance advantages.