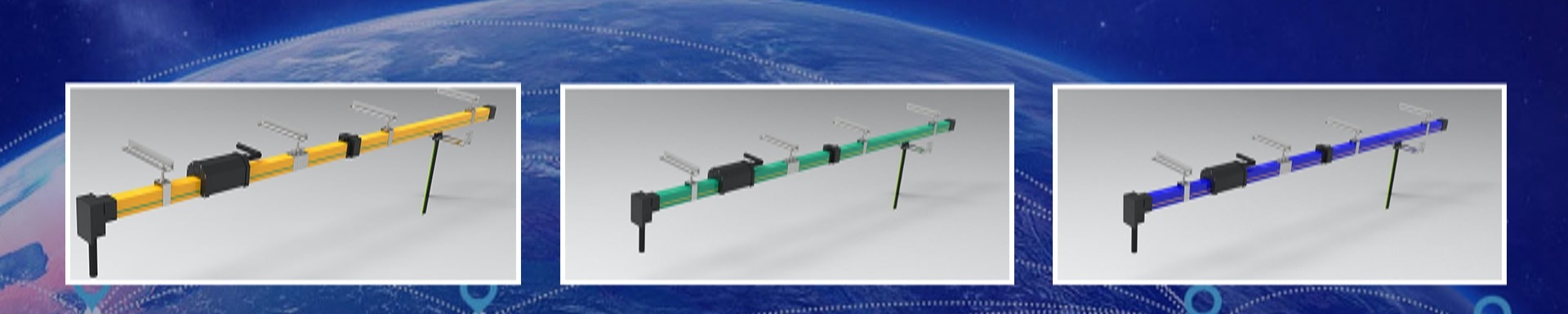

U12 sliding contact line

The "U12" type sliding contact wire produced by Wuxi Shuangjia Transmission Electric Appliance Co., Ltd. is according to the requirements of today's international standards, the design is fully in line with VDE0100, the anti-accidental contact protection is in line with VDE0740, part 1, and the protection level is IP21.

Application: The sliding line is widely used in automobile production lines, various small crane systems, packaging machinery, three-dimensional warehouses, sorting equipment, terminals, amusement parks, and manned mobile equipment and other places.

- Information

The slip-contact collector brush will protect against accidental injury only when it is fully in contact with the slip-contact conductor. If you need to touch a conductive part by hand, such as a collector when it is out of the slide line during operation, you need to take safety protection or power off (only if the voltage exceeds 25V AC or 60V DC).

The shell guard of various conductors is an excellent insulator. Thus, the "U12" line guarantees maximum safety in operation. Any number of slide wires can be installed side by side in the minimum space required by the customer.

The standard sliding contact line segment is 6m long, and the sliding contact line can also be made according to the requirements.

The zero line is identified by the international code color yellow.

For safety reasons, phase and zero line collectors are not interchangeable.

The U12 type sliding contact line is a common single-pole safety sliding contact line, featuring a U-shaped copper conductor and insulating housing design. It is suitable for medium and small current power supply (typically 50A to 400A). Compared with other sliding contact lines (such as H-type, multi-line type or steel body sliding contact lines), the U12 type has the following advantages:

1 The U12 type sliding contact line has a compact structure and is easy to install

U-shaped copper conductor + engineering plastic shell, small in size and light in weight, suitable for light cranes, suspended conveyors and other equipment.

It can be installed horizontally or vertically, adapting to different track layouts.

2 The U12 type sliding contact line has a high protection level

The shell is made of flame-retardant PVC or ABS material, dust-proof and splash-proof, and is suitable for general industrial environments (workshops, warehouses, etc.).

Compared with exposed steel sliding contact lines, it is safer and reduces the risk of electric shock.

3. The U12 type sliding contact line is economical and practical with high cost performance

Compared with multi-wire or high-current sliding contact lines, the U12 type has a lower cost and is suitable for small and medium-sized enterprises with limited budgets.

· Simple maintenance, convenient replacement of the collector (brush), and reduced long-term usage costs.

4. The U12 type sliding contact line operates smoothly with low noise

It adopts copper conductors and graphite collectors, featuring low friction, smooth sliding and lower noise than steel sliding contact lines.

It is suitable for noise-sensitive environments (such as clean workshops and laboratories).

5. The U12 type sliding contact line is suitable for medium and small current demands

It is suitable for light cranes, electric hoists, automated production lines and other equipment, with a moderate current carrying capacity.

If a larger current (such as >500A) is required, H-type or steel body sliding contact lines should be selected.

6. The U12 type sliding contact line has good wear resistance and a long service life

The U-shaped copper conductor has a large contact surface, ensuring uniform wear of the collector and a longer service life than the flat cable-type sliding contact line.

Regular maintenance (cleaning and inspecting the brushes) can further extend their service life.

7. The U12 type sliding contact line has strong scalability

It can be paired with signal sliding contact lines (such as the U12S type) to achieve synchronous transmission of power and control signals, meeting the requirements of simple automation.

Summary

The U12 type sliding contact line is an economical, lightweight and safe power supply solution for medium and small currents, especially suitable for scenarios such as light lifting equipment and automated production lines. If the equipment power is relatively large (>400A) or the environment is harsh (such as in metallurgy or ports), it is recommended to choose H-type or steel body sliding contact lines.

The U12 type sliding contact line is a single-pole combined sliding contact line, composed of U-shaped copper tubes, PVC insulating sheaths, external collectors and other components. It has the following advantages:

The U12 type sliding contact line has a compact and flexible structure: it is small in size, compact in structure, and has a small pole spacing. It can be combined arbitrarily according to requirements. Moreover, it is flexible in laying and can be suspended, attached to the wall, or installed horizontally or vertically. It is suitable for intensive installation scenarios such as electric monorail trolleys, automatic production lines, and amusement lines.

The U12 type sliding contact line has excellent bending performance: the bending radius can reach R500mm, and it can be bent freely along the track without the need to be specially made into an arc shape. It can well adapt to complex track layouts and meet the power supply requirements of some equipment with arc-shaped or curved tracks.

The U12 type sliding contact line has stable and reliable performance: The conductor is usually made of copper, which has excellent electrical conductivity and can effectively reduce power loss. Meanwhile, it is equipped with a corresponding PVC insulating sheath, which has good insulation performance and can prevent leakage and other situations from occurring. The overall performance is stable, capable of providing reliable power supply for mobile devices. It is widely used in conveyor lines and inspection lines in industries such as automobiles, post and telecommunications, machinery, and chemicals for mobile power supply and signal transmission.

The U12 type sliding contact line is easy to install and maintain: usually, each line is 6 meters long and can be combined freely through the installation base. The installation process is relatively simple. Moreover, components such as external collectors are easy to inspect and replace, and the later maintenance cost is relatively low.

The U12 type sliding contact line has good protective performance: The insulating sheath can protect the internal conductor from the influence of the external environment, and it can resist wind, frost, rain and snow. It has certain anti-freezing and anti-corrosion capabilities and can be used in poor environments such as open-air, water mist and acid mist.