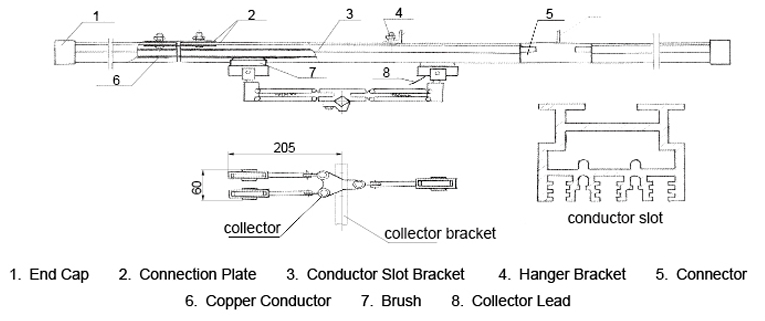

multi-line sliding contact line

SJP multipole conductor system takes oxygen-free copper as conductor rail,housed by PVC,features easy installation,high speed,stable running,compact structure,widely used in small and middle size cranes and unmanned factories,stereoscopic warehouse logistic,etc.

- Information

| ltem | Data |

| Voltage Resistant | >25KV/min |

| IP | IP23 |

| Current Resistant | 10 times rated current,1s |

| Max Current | 1.5 times rated current,30min |

| Insulation Dielectric Strength | Industrial frequency ac 3000v,1min no breakdown and flashover |

| Insulation Resistance | R>10MΩ |

| Pollution Grade | IV(general inductive dust,condensation) |

| Working Voltage | DC:1000V or AC:66V |

| Fire Retardant | Bunsens burner,qualified,good fire-retardant |

| Speed Of Collector | V:120m/min |

| Model | Code | Cross-section mm² | Rated Current A | Resistance Ω/km | Impedance Ω/km |

| SJP-4-10/50 | 0881101 | 10 | 50 | 1.800 | 1.896 |

| SJP-4-16/80 | 0881102 | 16 | 80 | 1.250 | 1.189 |

| SJP-4-25/125 | 0881103 | 25 | 125 | 0.720 | 0.770 |

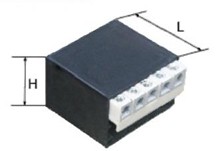

| Model | Code | Dimension | |

| L | H | ||

| XD-1 | 0882101 | 52 | 36 |

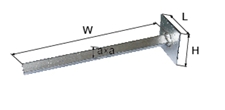

| Model | Code | Dimension | |

| L | H | ||

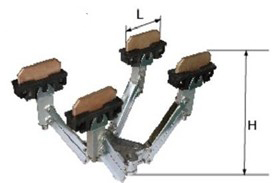

| SJ-4-80 | 0882102 | 75 | 220 |

| Model | Code | Dimension | |||

| L | axa | H | W | ||

| QX-1 | 0882103 | 100 | 25×25 | 100 | 350 |

| Model | Code | Dimension | |

| L | H | ||

| GD-1 | 0882104 | 88 | 56 |

Multi-wire sliding contact lines refer to power transmission devices that integrate multiple conductive lines (such as copper bars, aluminum bars or copper stranded wires) within the same insulating housing. They can simultaneously provide independent power supply for multiple devices or multiple power units of the same device (such as motors, control circuits, lighting systems, etc.). Its core advantages are reflected in aspects such as integration, security, flexibility and economy. The following is a detailed description:

1. The multi-line sliding contact line is highly integrated, saving space and cost

· Multi-circuit integration: Integrate 2 to 12 independent conductive lines (commonly 3 to 6 lines) within a single sliding contact line, which can simultaneously transmit power sources (such as three-phase electricity), control signals, neutral wires, ground wires, etc., replacing multiple separate sliding contact lines or cables, significantly reducing the space occupied by the track and the installation workload.

· Compact layout: Multiple conductors are arranged side by side in the same insulating housing, resulting in a small overall volume. This is particularly suitable for workshops with limited space, multi-layer three-dimensional storage systems, or dense production lines, avoiding the clutter caused by traditional multi-cable suspension.

· Reduce initial investment: Only one set of sliding contact line brackets, collectors and protection systems is needed to meet the power supply requirements of multiple circuits. Compared with laying multiple sets of sliding contact lines separately, the material cost and installation cost can be reduced by 30% to 50%.

Second, the multi-line sliding contact line is safe and reliable, with strong anti-interference ability

· Independent insulation protection: Each conductor has an independent insulation layer (such as PVC, cross-linked polyethylene), and is then wrapped in an integral insulation shell (such as flame-retardant rubber or engineering plastic) on the outside, forming double insulation protection. This can effectively prevent interphase short circuits, leakage or electric shock risks, and is especially suitable for humid, dusty or slightly corrosive environments.

· Grounding and anti-interference design: A dedicated ground wire (PE wire) can be set up separately to ensure reliable grounding of the equipment. The control signal lines and power lines are isolated and arranged to reduce electromagnetic interference, making it suitable for automated equipment with high requirements for signal stability (such as PLC control systems and sensor networks).

· Anti-loosening structure: The conductor is fixed inside the insulating housing through slots or bolts to prevent the conductor from shifting or having poor contact due to equipment vibration, thereby enhancing the reliability of power supply.

Three, the multi-wire sliding contact line can flexibly adapt to the power supply requirements of multiple devices

· Independent power supply for multiple devices: Each conductor can correspond to one device or one power unit. For example, three phase lines supply power to the motor, one neutral line, one ground line, and one control line supply power to the solenoid valve, achieving "one sliding contact line meeting the diverse power supply requirements of the entire set of equipment".

· Dynamic load distribution: According to the current requirements of different circuits, the cross-sectional area of conductors can be flexibly configured (for example, large cross-sectional copper bars are used for power lines and small cross-sectional copper stranded wires for signal lines), avoiding cost waste caused by "large lines used for small ones".

· Convenient for expansion and renovation: If new equipment or circuits need to be added, spare conductors can be reserved inside the existing sliding contact line housing, or rapid expansion can be achieved through connection sections without the need to re-lay the entire system. This is suitable for scenarios such as later production line upgrades or equipment additions and subtractions.

Fourth, the multi-wire sliding contact line has stable electrical conductivity and is highly efficient to maintain

· Low impedance transmission: The conductors are made of high-purity copper or aluminum materials (copper bars have a higher conductivity, while aluminum bars are less expensive), and the cross-sectional area is customized according to the current demand (commonly 10 to 200mm²). It has low resistance and energy loss, and can carry a current of 200 to 1000A, meeting the requirements of medium and high-power equipment.

· High contact reliability: The collector is equipped with multiple independent brushes that come into contact with the corresponding conductors one by one. The contact pressure is uniform. Even if the equipment shakes or the track deviates slightly, it can still maintain stable conductivity, reducing electric sparks and wear.

· Centralized maintenance: The inspection and maintenance of all circuits are centralized within the same sliding contact line system, eliminating the need to check each cable one by one. On a daily basis, only the integrity of the overall casing and the wear of the collector brushes are required, increasing maintenance efficiency by more than 50%.

Five, multi-line sliding contact lines are widely applicable in various scenarios

· Automated production line: It simultaneously provides power and control signals for multiple devices in the assembly line (such as conveyor belt motors, detection instruments, and robotic arms), simplifying wiring.

· Three-dimensional storage system: It simultaneously supplies power and transmits communication signals for AGV carts, stackers and other equipment, adapting to the compact space layout of multi-layer shelves.

· Port and logistics equipment: Supply power to multiple circuits such as the main motors, lighting, and monitoring systems of large equipment like cranes and gantry cranes, reducing the complexity of high-altitude cable suspension.

· Hybrid power supply scenario: Simultaneously transmit three-phase AC power (380V), single-phase power (220V), and low-voltage control signals (such as 24V DC), suitable for comprehensive equipment that requires multiple power sources.

Summary

The multi-wire sliding contact line solves the complexity problem of traditional multi-circuit power supply through integrated design, and has the advantages of safety, flexibility and economy. It is especially suitable for automation scenarios that need to simultaneously transmit multiple power sources or signals. If the project involves multi-device collaborative power supply, space limitations or future expansion requirements, multi-wire sliding contact lines are the preferred solution. If only a single power supply is required and the current is extremely large (such as in large metallurgical equipment), a single-pole rigid body sliding contact line combination scheme can be considered.

The multi-wire sliding contact line is a sliding contact line system that uses multiple parallel conductors arranged in parallel. It is usually composed of multiple groups of copper bars or insulated cables and can provide multiple independent power sources or signal transmissions for mobile devices. Compared with the single-pole sliding contact line, it has the following advantages:

The multi-wire sliding contact line is powered by multiple circuits and has strong flexibility

It can simultaneously transmit multiple power sources (such as three-phase AC 380V + control power) or signals (such as data and communication signals).

It is suitable for equipment that requires independent power supply (such as cranes and automated production lines), avoiding additional wiring.

2. The multi-wire sliding contact line ensures uniform current distribution and reduces voltage drop

When multiple conductors work in parallel, the current load on a single conductor is reduced, minimizing heat generation and voltage loss.

It is suitable for high-power equipment (such as metallurgical cranes and large conveyors).

3. The multi-line sliding contact line has a compact structure and saves space

Multiple conductors are integrated in a single sliding contact line slot, which saves more installation space than installing multiple sets of single-pole sliding contact lines separately.

It is suitable for occasions with narrow tracks or limited space.

4. The multi-line sliding contact line features high reliability and redundant design

If one conductor malfunctions, the other conductors can still maintain power supply, enhancing the stability of the system.

It is applicable to critical equipment (such as port cranes and automated warehousing systems) to reduce the risk of downtime.

5. Multi-wire sliding contact lines are suitable for complex control systems

It can integrate power, control signals and data communication into one, reducing the use of external cable drag chains.

For example:

◦ Three-phase power supply (L1/L2/L3)

◦ Neutral line (N)

◦ Ground wire (PE)

◦ 24V DC control power supply

◦ RS485/CAN bus communication line

6. The multi-line sliding contact line is easy to install and maintain

The modular design allows for the replacement of a single conductor without the need for overall disassembly.

The maintenance does not affect the normal operation of other circuits.

7. The multi-line sliding contact line has strong adaptability and can be used in various environments

The protection level can reach IP54/IP65, making it suitable for damp, dusty and corrosive environments (such as workshops, ports and mines).

Some models support special requirements such as high-temperature resistance and explosion-proof.

Summary

Multi-wire sliding contact lines are particularly suitable for occasions where multiple independent power supplies or signal transmissions are required. They have advantages such as high reliability, strong flexibility, and space-saving, and are widely used in heavy industry, automation, logistics, and rail transit fields. If the equipment only requires a single power supply, a single-pole sliding contact line may be more economical. If integration of power, control and communication is required, multi-wire sliding contact lines are the best choice.