Flexible sliding line

SJP multipole conductor system takes oxygen-free copper as conductor rail,housed by PVC,features easy installation,high speed,stable running,compact structure,widely used in small and middle size cranes and unmanned factories,stereoscopic warehouse logistic,etc.

- Information

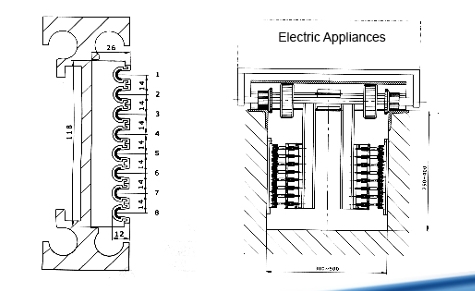

| ltem | Data |

| Housing Breakdown Voltage | >25KV/min |

| Housing IP | IP23 |

| Current Withstand | 10 times rated current,1s |

| Dielectric Strength | 3000vAC industrial frequency,1min,no breakdown |

| Insulation Resistance | R>10MΩ |

| Pollution Grade | IV(general conductive dust &condensation) |

| Working Voltage | DC:1000V or AC:600V |

| Fire Retardant | Bunsens burner,qualified,good fire-retardant |

| Collector Working Speed | V≤200m/min |

| Model | Code | Cross-section mm² | Rated Current A | Resistance Ω/km | Impedance Ω/km |

| SJR-4-10/50 | 0871101 | 10 | 50 | 1.800 | 1.896 |

| SJR-4-16/80 | 0871102 | 16 | 80 | 1.250 | 1.189 |

| SJR-8-10/50 | 0871103 | 10 | 50 | 3.600 | 3.792 |

| SJR-8-16/80 | 0871104 | 16 | 80 | 2.500 | 2.378 |

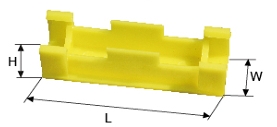

| Model | Code | Dimension | ||

| L | H | W | ||

| LJ-1 | 0872101 | 70 | 20 | 20 |

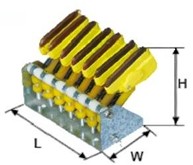

| Model | Code | Dimension | ||

| L | H | W | ||

| GD-1 | 0872102 | 150 | 12 | 33 |

| Model | Code | Dimension | ||

| L | H | W | ||

| DD-1 | 0872103 | 100 | 15 | 20 |

| Model | Code | Dimension | |

| L | H | ||

| DM-1 | 0872104 | 40 | 17 |

| Model | Code | Dimension | ||

| L | H | W | ||

| SJS-7-25 | 0872105 | 140 | 100 | 73 |

Flexible sliding contact lines (also known as safety sliding contact lines or cable sliding contact lines) are flexible conductive systems used to power mobile devices, typically composed of multi-pole insulated wires or flat cables, and are used in conjunction with sliding collectors. Compared with steel body sliding contact lines, flexible sliding contact lines have the following advantages:

1、The flexible sliding contact line is easy to install and can adapt to complex tracks

The flexible design can adapt to arc-shaped, curved and helical tracks, making it suitable for equipment with non-linear motion (such as circular production lines and rotary tables).

Steel sliding contact lines are usually only suitable for straight or simply bent tracks, while flexible sliding contact lines can be freely bent and are more convenient to install.

2. Flexible sliding contact lines are suitable for medium and small current applications

The current range is typically 50A to 800A (up to 5000A for steel sliding contact lines), making it suitable for medium and small power equipment such as light cranes, automated equipment, and logistics conveyor lines.

For low current demands, flexible sliding contact lines are more economical and practical.

3. The flexible sliding contact line operates smoothly with low noise

It adopts flexible cables or conductive tapes for sliding, with less friction and quieter operation, making it suitable for noise-sensitive environments (such as workshops and laboratories).

The steel sliding contact line may produce a relatively large friction sound due to metal contact.

4. The flexible sliding contact line has high safety and good protection

The outer layer is made of wear-resistant and flame-retardant insulating materials (such as PVC, TPE), with a protection level up to IP54, which is dust-proof, water-proof and shock-proof.

It has no exposed conductors, avoiding the risk of short circuits and is suitable for damp and dusty environments.

5. The flexible sliding contact line is easy to maintain and replace

The flexible sliding contact line adopts a modular design. When damaged, only a single section of the cable needs to be replaced, resulting in low maintenance costs.

If the steel sliding contact line is damaged, the entire section may need to be replaced, making the maintenance more complicated.

6. The flexible sliding contact line is lightweight and imposes a small load on the support

The flexible sliding contact line is made of lightweight materials (such as copper cable + plastic shell), has low requirements for the supporting structure, and is suitable for light equipment.

The steel sliding contact line is relatively heavy and requires a more sturdy bracket for support.

7. The flexible sliding contact line has strong resistance to vibration and shock

The flexible structure can absorb the vibration during the operation of the equipment and reduce the problem of poor contact caused by vibration.

The steel sliding contact line may become loose or deformed in a strong vibration environment.

8. The flexible sliding contact line has good economy

For small and medium-sized equipment and short-distance power supply, the cost of flexible sliding contact lines is usually lower than that of steel sliding contact lines.

Summary

Flexible sliding contact lines have obvious advantages in terms of flexibility, safety and economy, and are particularly suitable for small and medium currents, curved tracks or occasions that require low noise. Steel body sliding contact lines are more suitable for heavy industrial applications with large currents, heavy loads and linear tracks. Just choose the appropriate type according to your specific needs.

Flexible sliding contact lines are power transmission devices suitable for mobile equipment power supply. Compared with rigid sliding contact lines, their most prominent feature is good flexibility and battenability, which can adapt to complex tracks or frequent movement scenarios. The following are its core advantages:

1. The flexible sliding contact line has strong flexibility and is suitable for complex tracks

· Flexible design: Utilizing soft conductors (such as multi-strand copper stranded wires) and elastic insulating materials (such as rubber, PVC or silicone), it can be flexibly bent and twisted along the track, adapting to irregular track layouts such as S-shaped, arc-shaped, and ring-shaped. It can even be used in power supply scenarios for equipment's up and down lifting or rotational movements.

· Lightweight structure: The overall weight is light and the volume is small. There is no strict straightness requirement during installation, and the strength requirement for the track support is relatively low. It is suitable for small and medium-sized equipment or environments with limited space (such as small cranes, electric hoists, automated assembly lines, etc.).

Second, the flexible sliding contact line is easy to install and offers flexible layout

· Simple and quick installation: No complex modular splicing is required. It can be directly laid along the track and installed through simple fasteners such as clips and hooks. The construction difficulty is low and the construction period is short. It is especially suitable for the rapid power supply deployment of renovation projects or temporary equipment.

· Flexible length adjustment: The length can be freely cut according to actual needs. There is no need for complex head treatment at the end, and it supports multi-segment connection, adapting to the length changes of tracks with different spans.

· Excellent spatial adaptability: It can be installed close to the edge of equipment or tracks, saving space. It is especially suitable for the power supply requirements of equipment in narrow workshops or multi-story three-dimensional storage systems.

Third, the flexible sliding contact line is safe and reliable, with stable protective performance

· Excellent insulation: The outer layer of the conductor is wrapped with high-strength insulating materials (such as flame-retardant rubber, cross-linked polyethylene), which has a high insulation grade and can effectively prevent leakage and short circuits. It is suitable for humid, dusty or slightly corrosive environments (such as food processing workshops, logistics warehouses, etc.).

· Anti-vibration and shock: The flexible structure can buffer the vibration and shock during the movement of the equipment, reduce the hard collision between the conductor and the collector, lower the risk of poor contact or wire breakage, and extend the service life.

· Anti-wear design: The contact part between the collector (receiver) and the sliding contact line adopts flexible brushes or elastic contacts, which ensures smooth contact, minimal wear, and can be quickly maintained by replacing the brushes without the need to replace the entire sliding contact line.

Fourth, the flexible sliding contact line has stable electrical conductivity and low energy consumption

· Multi-strand conductor structure: It adopts multi-strand twisted copper conductors (with a cross-sectional area typically ranging from 10 to 150mm²), featuring a large equivalent conductive area, low resistance, stable current transmission (capable of carrying 200 to 800A currents), low energy loss, and is suitable for the power supply requirements of medium-power equipment.

· High contact reliability: The flexible conductor can maintain close contact with the collector through its own elasticity during movement. Even if the equipment shakes slightly or the track deviates slightly, it can still ensure the continuity of conductivity and reduce the generation of electric sparks.

Five, the flexible sliding contact line has a significant cost advantage and is easy to maintain

· Low initial investment: The material cost and installation cost are lower than those of rigid sliding contact lines, making it particularly suitable for small and medium-sized enterprises with limited budgets or short-term usage scenarios (such as temporary production lines and mobile equipment).

· Low maintenance cost: The structure is simple, with no complex mechanical components. Daily maintenance only requires regular checks on the integrity of the insulation layer and the wear of the collector brushes. The maintenance workload is small, and the cost of replacing parts is low.

· Recyclability: Both insulating materials and conductors can be recycled and reused, meeting environmental protection requirements and having low waste disposal costs.

Six. Flexible sliding contact lines are widely applicable in various scenarios

· Small and medium-sized mobile equipment: such as electric hoists, small cranes, lifting platforms, automated warehouse AGV carts, etc.

· Complex track environments: such as rotating cranes with arc-shaped tracks, lifting equipment for multi-storey car parks, circular production lines, etc.

· Light-load or low-speed scenarios: The equipment's moving speed is typically ≤50 meters per minute, making it suitable for scenarios with high requirements for power supply reliability but without the need for large currents (such as light industrial production lines and logistics sorting systems).

Summary

Flexible sliding contact lines, with their features of flexibility, low cost and easy installation, have become the preferred solution for small and medium-sized mobile devices and complex track scenarios. If it is necessary to adapt to high-power, harsh industrial environments or high-speed mobile devices, rigid sliding contact lines can be given priority. If economy and track adaptability are emphasized, flexible sliding contact lines have more advantages.